Air Make Up Spray & Cure Heat Systems.

Marathon’s Spray & Cure heated make up air systems are the best in the industry. Whether you’re buying a new spray paint booth, or you are looking to upgrade an existing booth installation, Marathon can provide you with the solution that you need.

Marathon Products are ETL listed

and comply with all applicable

quality and safety standards.

A Superior Spray Paint Curing System…

Marathon’s “Direct Fired” booth heating systems provide precise controls for ventilation and temperature manipulation for both custom finishing operations as well as dedicated spray paint booth applications. Our Spray & Cure systems are among the best in the automotive industry. In the spray mode they deliver fresh make up air for high volume, low temperature ventilation that enhances operator safety and finish quality.

In the cure mode, our units provide heated curing air for high temperature ventilation that speeds finish drying, increases finish quality, and minimizes overall production times. Marathon offers a wide range of system configurations, as well as selected options such as cooling and humidity control for custom optimization of Spray & Cure performance.

We can design a specialized solution for operating requirements that range from a single 4,000 CFM unit to 15,000 CFM using multiple units. We are committed to your complete satisfaction. Change the way you work: Higher quality, faster runs, increased productivity, and a higher profit margin.

Understanding the Spray & Cure Cycle…

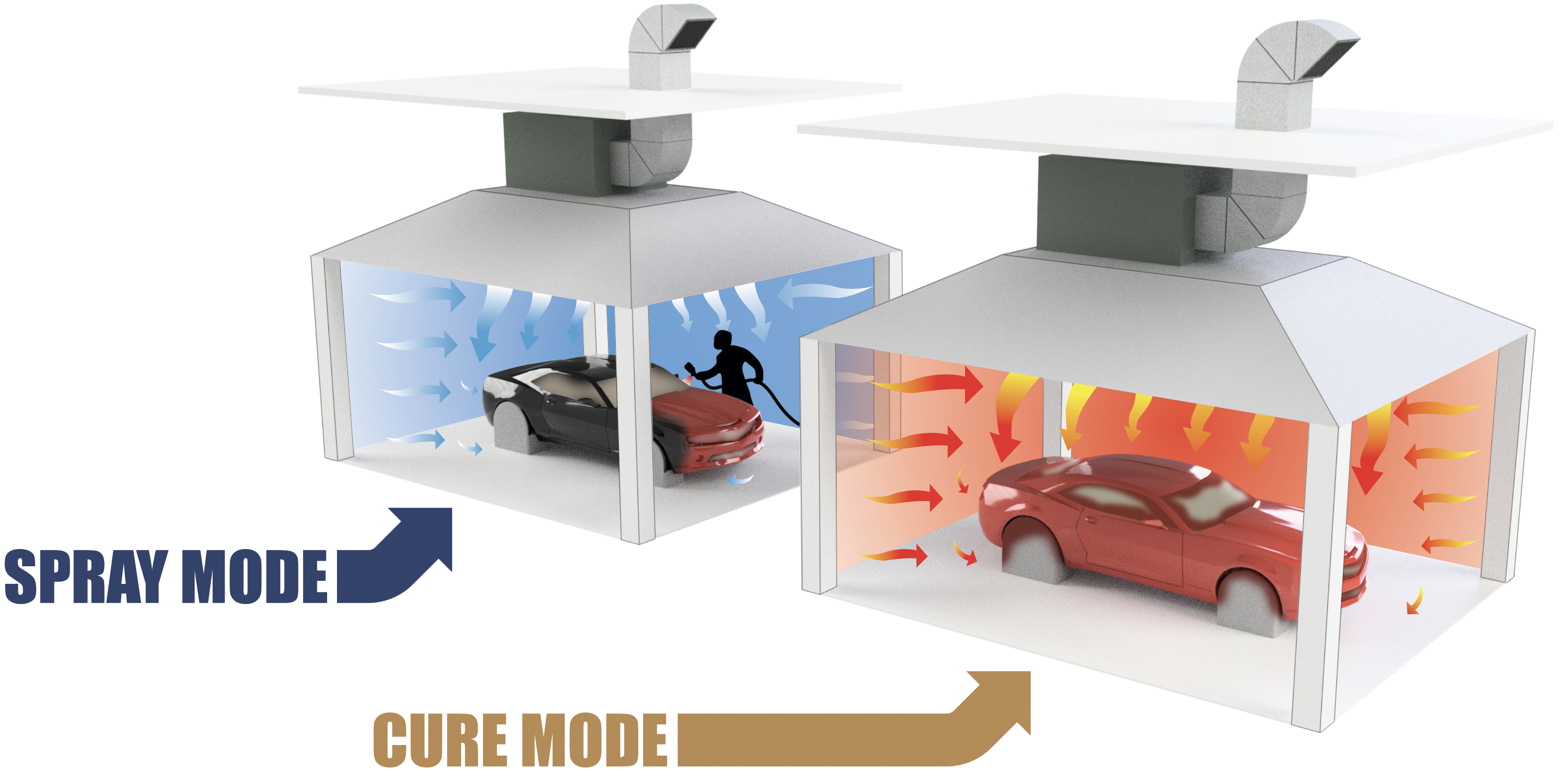

Spray Mode

During the spray cycle, our direct fired system typically provides 100% filtered outside air that is temperature controlled to between 60° and 90° supplied in a constant high volume for maximum booth ventilation.

Cure Mode

During the finishing, or Cure cycle, our direct fired system typically provides either reduced 100% filtered outside air, or a higher volume 80/20 blend of recirculated and outside air that is heated to between 80° and 200° F, intended to reduce finish drying and curing times.

Applications

Marathon’s direct fired Spray & Cure finishing solutions provide outstanding results in all types of spray paint booths and environments, including downdraft, modified down draft (also known as a semi down draft), and crossflow configurations. Our systems are designed and built to your exact application requirements for precise booth conditioning needs. Our Spray & Cure systems are the most economical and versatile heating units for spray booth applications, with precise control of low to moderate finishing curing temperatures (80° to 140°F).

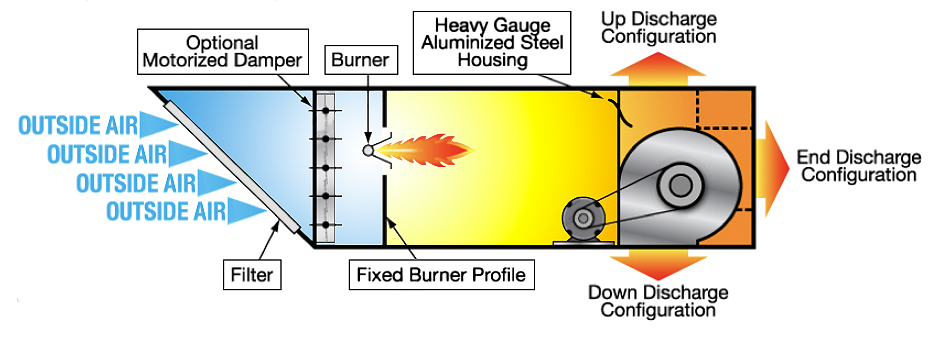

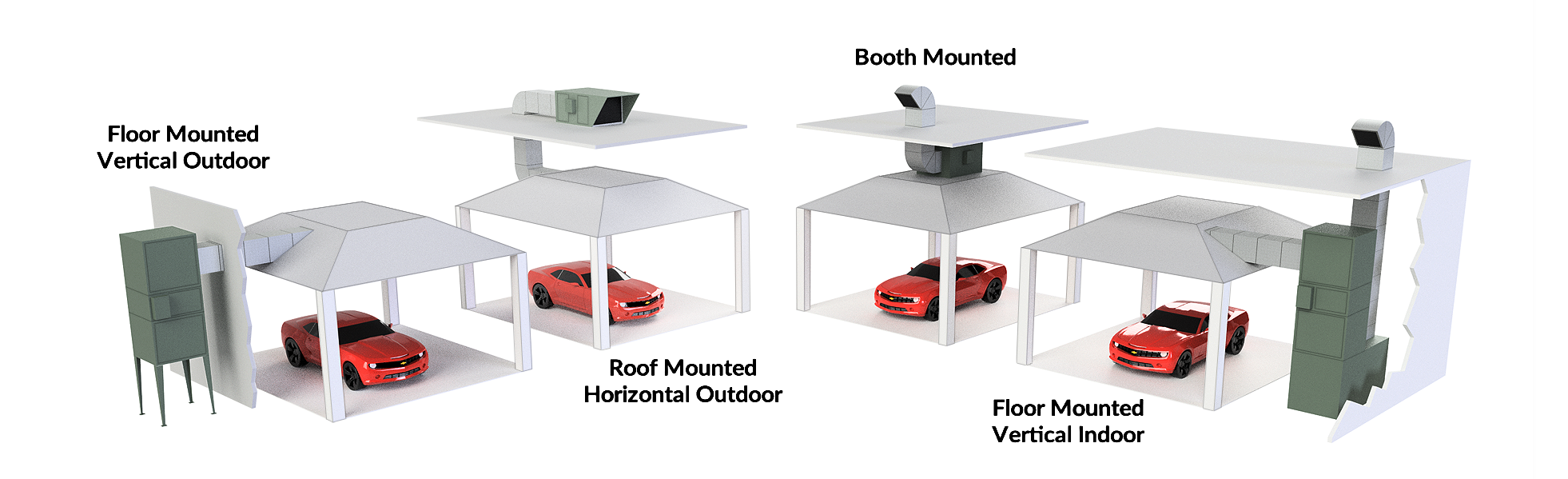

Designed to provide uniform airflow across the burner, our heating units ensure maximum fuel efficiency, while “draw through” ventilation with a forward curved centrifugal fan ensures precise air delivery volume. Marathon can configure your heating unit to fit any type of environment. Some common heater configurations are shown below:

Marathon Finishing Systems is dedicated to your satisfaction! If need more information, or you would like to discuss the various options available to fit your requirements, call today us at 310 791-5601 and let’s talk about how to take your spray painting operation to the next level. Marathon will get you there!