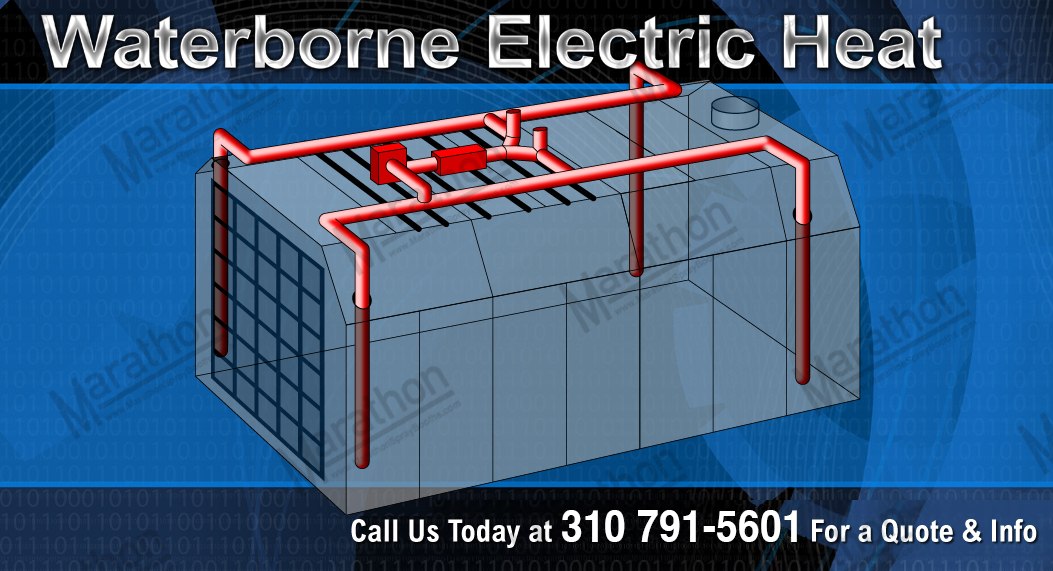

Waterborne Paint Drying – Electric Heat

Marathon’s Waterborne Paint Drying systems are the addition that can make the difference when working with new waterborne paints, and overcoming the difficulties relate to their effective use. If you are working hith waterborne, or are even considering “making the switch” this information must be a key factor in that process.

Marathon Products are ETL listed

and comply with all applicable

quality and safety standards.

The theory behind our Waterborne Paint Drying is that we introduce “pulse turbulence” into the air flow. This turbulence travels within the secondary air flow of the primary air nozzles. A rapid “on-off’ feed cycle of air is critical to effectively altering the air flow, thereby increasing waterborne performance.

The “Perfect Air” temperature controller neutralizes the negative effects of humidity during the waterborne curing process, by giving you control of the water evaporation rate.

These systems are based on patent pending technologies that can dramatically increase performance, increase efficiency, and provide effective results that can be scientifically tested and verified.

These systems are the most effective and efficient technologies available today, especially where corner space is limited. Our “Stealh Tower” modules will fit into corner spaces as small as 4.6 inches. Call us for more details.