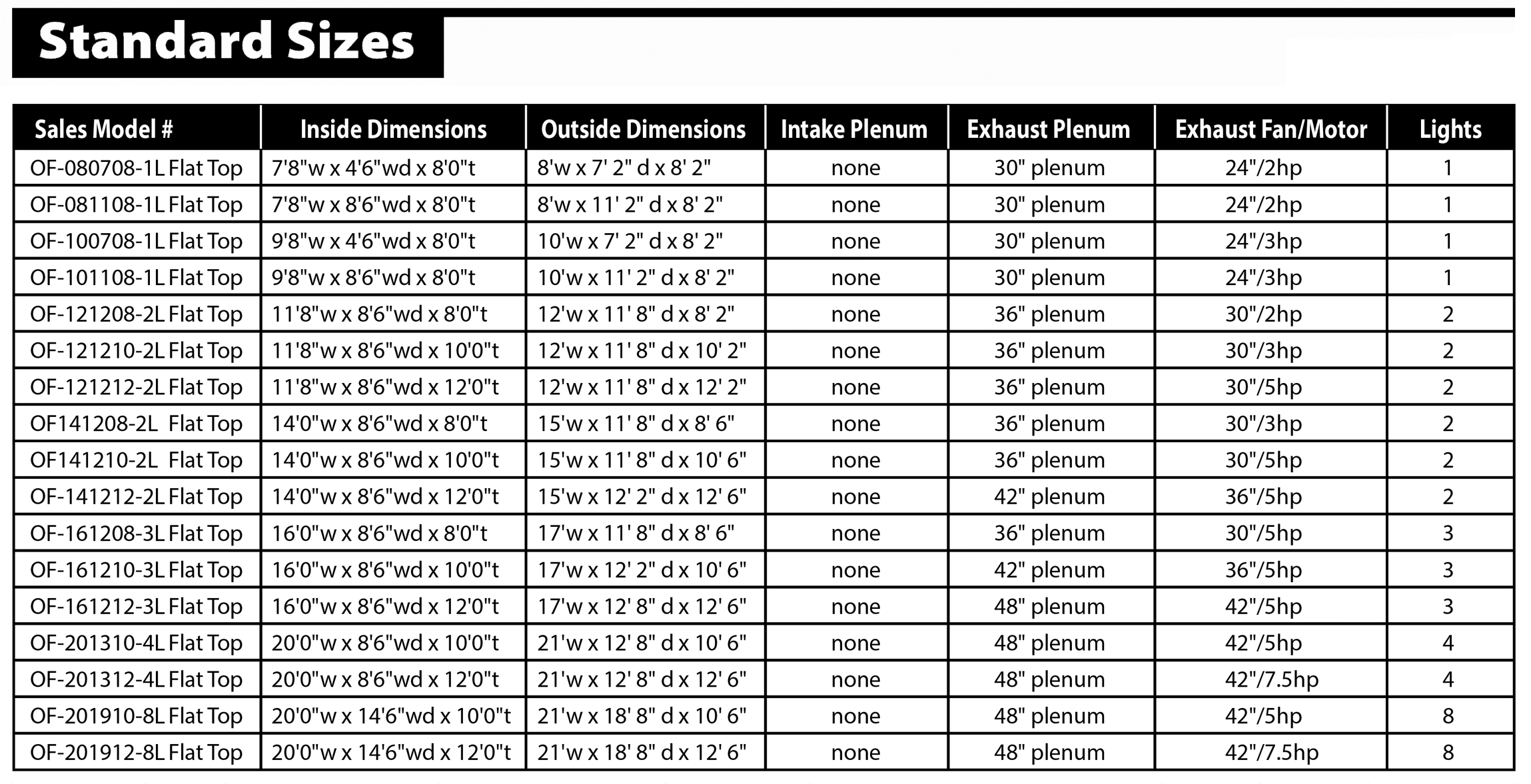

Open Face Woodworking & Cabinets Spray Paint Booths

Similar to the Closed Booths, Open Face Industrial Booths share many of the same characteristics, only with an open front (no doors). Marathon Finishing Systems can engineer a booth specifically designed to meet or exceed all of your expectations. Whether you need a large or small booth, you can expect a rugged, heavy duty product built with high quality components, made right here in the USA.

Marathon Spray Paint Booths are ETL listed and comply with all applicable quality and safety standards.

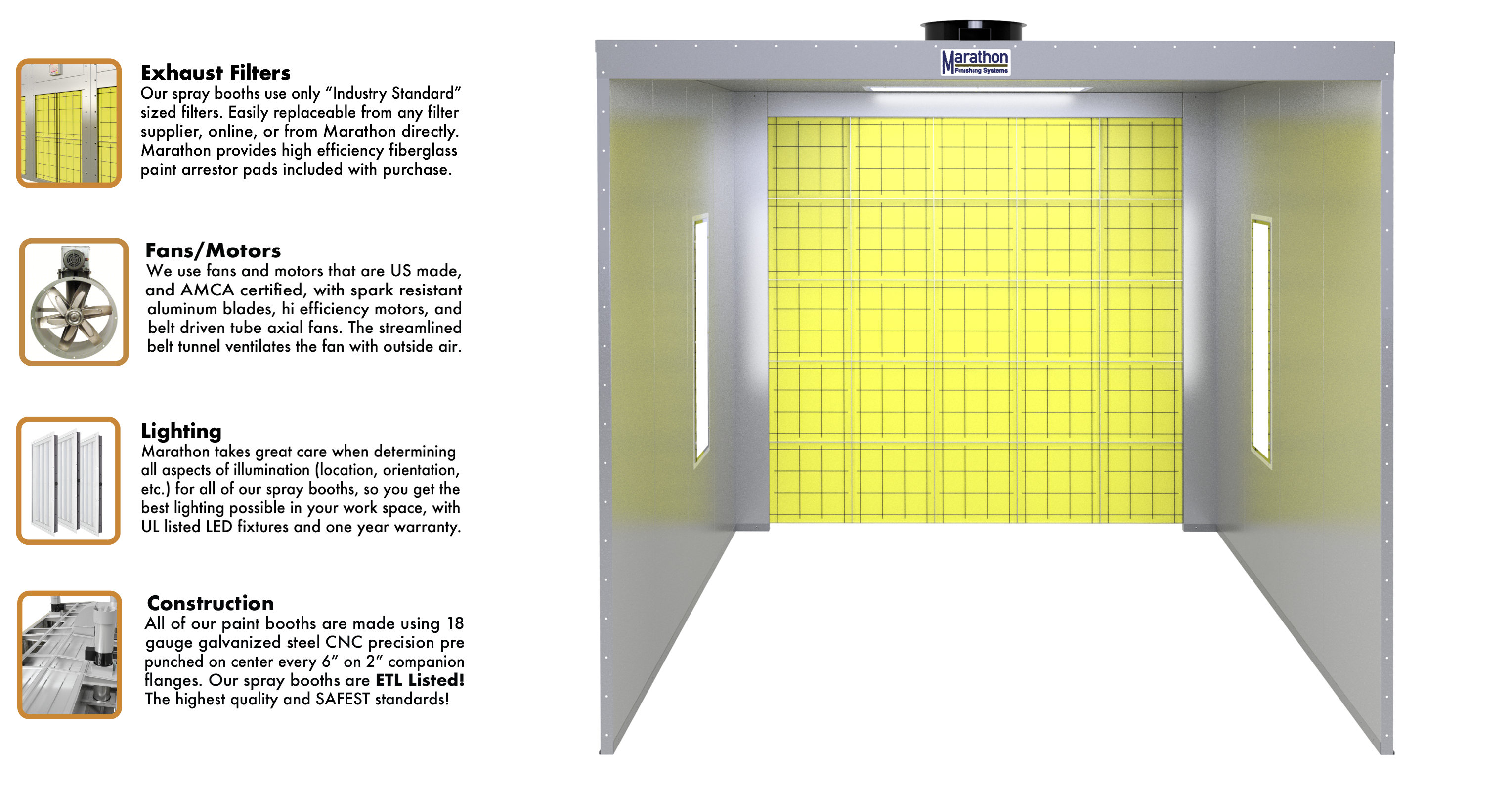

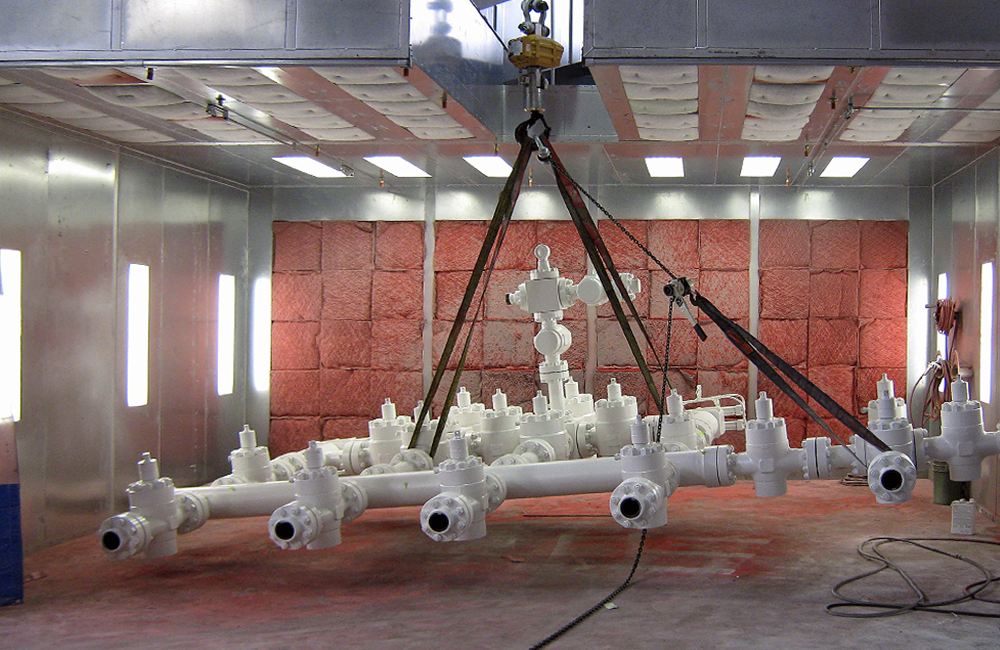

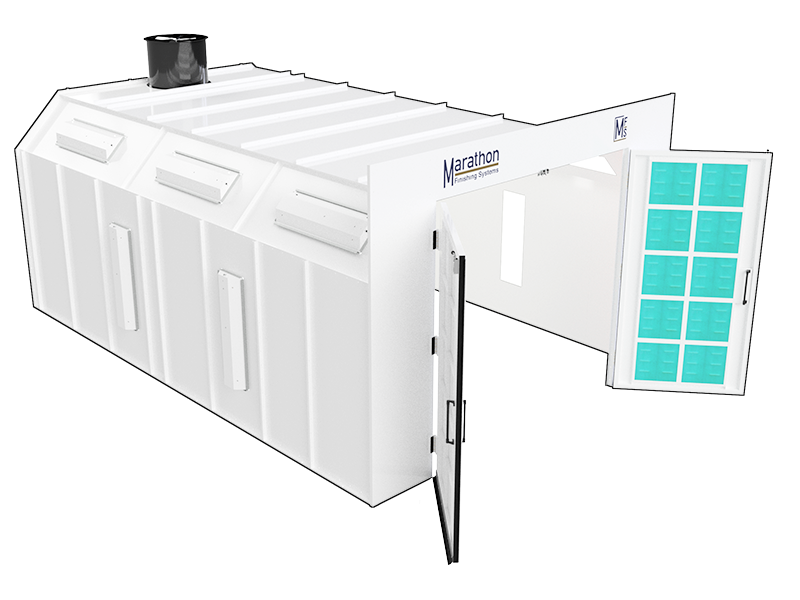

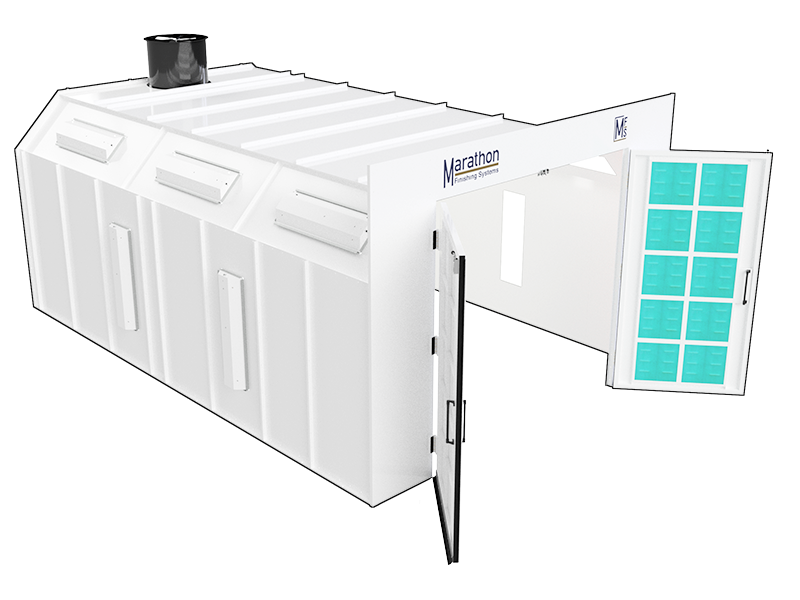

Industrial Open Face Spray Paint Booth

Industrial Open Face Spray Paint Booth (Curtain Not Shown)

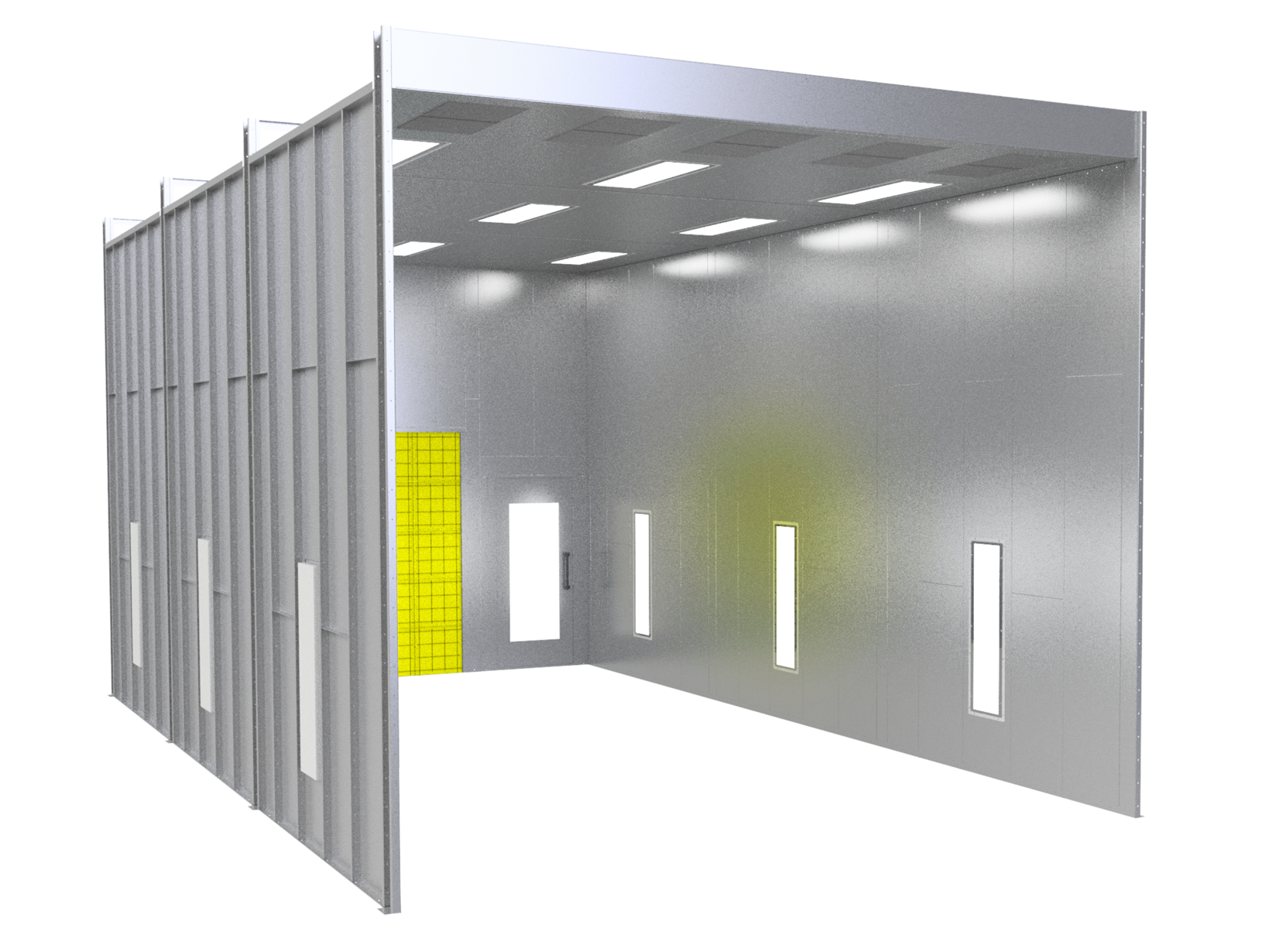

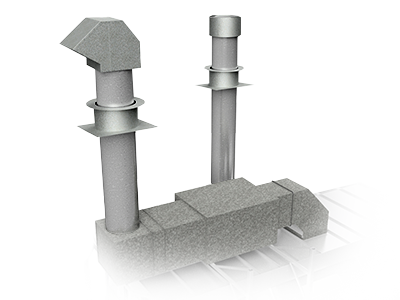

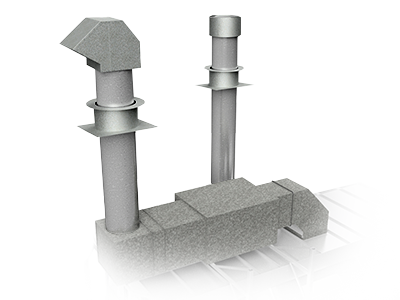

Air Flow – Open Face Industrial Spray Paint Booth

Ambient (surrounding environment) air is pulled into the front of the spray booth, flows horizontally across the booth (cross Flow), and is exhausted up and out of the booth.

Because of the simple, “Open Face” design of this spray paint booth:

• Keeping your shop as dust free as possible to

minimize airborne particulates from entering

the booth’s air stream.

• While heating the incoming air CAN be done,

it is usually cost prohibitive to do so.

Did you Know?

The ETL Listing (certification) is

confirmation that every aspect of

our construction meets or exceeds the

build and safety code standards established by

NFPA 33. This is important, as your Fire Inspector will require proof of compliance before approval.

Did you Know?

The ETL Listing (certification) is your confirmation that every aspect of our construction meets or exceeds the build and safety code standards established by NFPA 33. This is important, as your Fire Inspector will require proof of compliance before approval.

Available Options for This Booth Type to Consider

Powder Coating

Clean, beautiful, Bright White Powder Coating. Inside and outside, the entire booth!

Paint Mixing Rooms

Don’t forget a paint mixing room. An important addition to your painting operation.

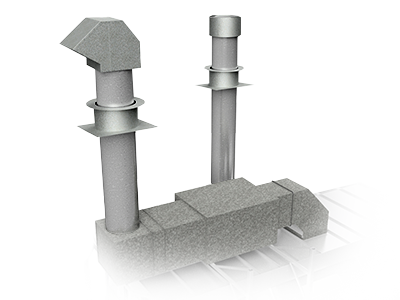

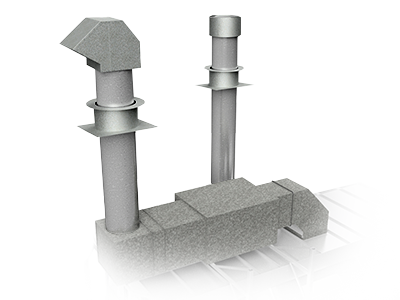

Ducting Options

Whether it’s a short run, or an entire facility air flow system, we have what you need.

Additional Filters

Don’t get caught off guard! Make sure you have enough filters on hand by ordering extra filters.

LED Lighting Fixtures

We offer many different styles and types of lighting fixtures to offer for your spray paint booth.

Booth Coat

You’ve spent a lot of money on your spray paint booth, so you should protect it. Clear or White.

Available Options for This Booth Type to Consider

Powder Coating

Clean, beautiful, Bright White Powder Coating. Inside and outside, the entire booth!

Paint Mixing Rooms

Don’t forget a paint mixing room. An important addition to your painting operation.

Ducting Options

Whether it’s a short run, or an entire facility air flow system, we have what you need.

Additional Filters

Don’t get caught off guard! Make sure you have enough filters on hand by ordering extra filters.

LED Lighting Fixtures

We offer many different styles and types of lighting fixtures to offer for your spray paint booth.

Booth Coat

You’ve spent a lot of money on your spray paint booth, so you should protect it. Clear or White.