Marathon Offers Man Lifts Made by Titan

Titan Air’s Personnel Lifts (also called “Man Lifts”) are tailored for the finishing industry. Titan’s Personnel lifts can become an essential element for companies to realize better efficiencies while at the same time creating a safer, more ergonomically friendly work environment.

Marathon Spray Paint Booths are ETL listed and comply with all applicable quality and safety standards.

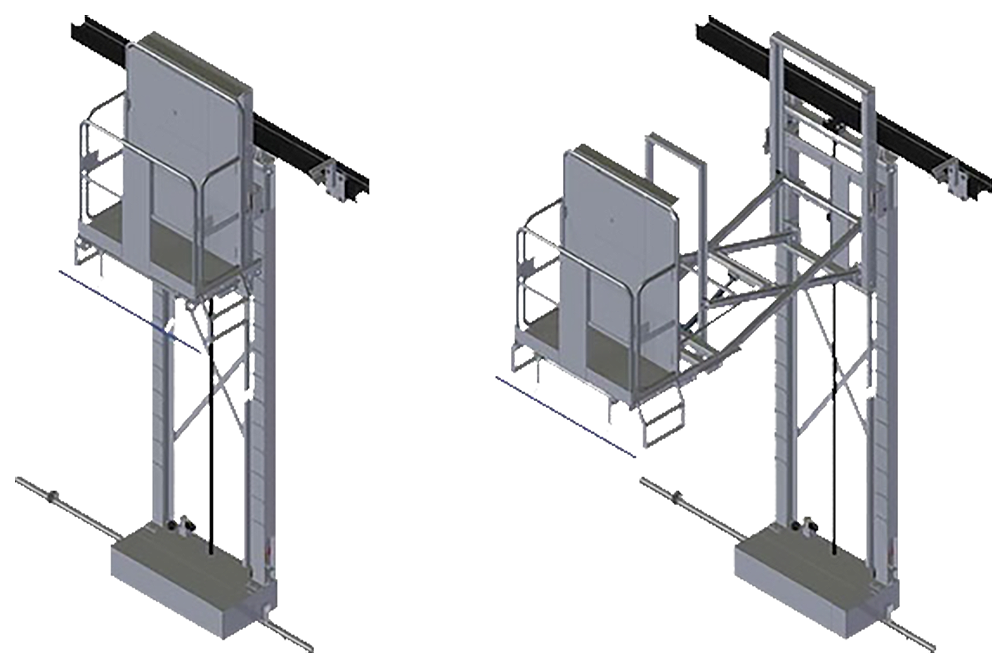

Collapsible During Non Use Operations

2 Axis and 3 Axis RollOut Models Available

Titan Personnel Lifts…

Titan Lifts are designed and manufactured to comply with ANSI standard 92.6 for “Self Propelled Elevating Work Platforms” and meet or exceed OSHA standards.

Titan Lifts are typically ordered with either 2-axis or 3-axis travel. The lift travels on a square tube bottom rail and wide flange beam upper rail. The lateral travel along the enclosure wall, or X-axis is at a variable rate of up to 40 feet per minute. The X-axis travel is achieved through the use of chain driven aluminum wheels powered by an air motor. The vertical travel, or Z-axis, is achieved through the use of a hardened steel rotary ballscrew powered by an air motor. The rate of travel is 15 feet per minute.

A three-axis lift, in addition to X and Z travel, will extend away from the booth wall at a rate of 15 feet per minute. This Y-axis travel is achieved through the use of an air actuator and scissor mechanism that extends the basket away from the booth wall. A standard lift will be extended by an actuator to a distance of up to 8 feet. The addition of an optional rollout assembly will enable the basket to travel an additional 21 inches. An extended reach lift will extend 12 feet 6 inches and up to 14 feet 3 inches with the added rollout assembly. Flex Tracking and custom basket sizes are also available.

Titan Air’s personnel lifts are tailored for the finishing industry; however custom lifts for other applications are also available. Enhanced design capabilities provide Titan Air the tools to create a simple and safe method of positioning personnel or product for most applications.

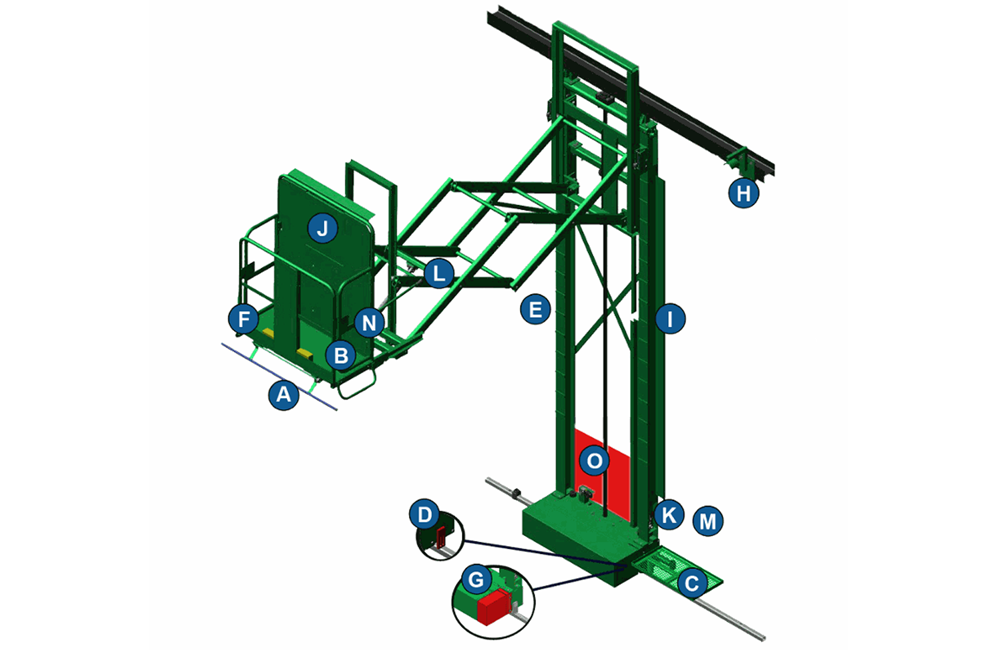

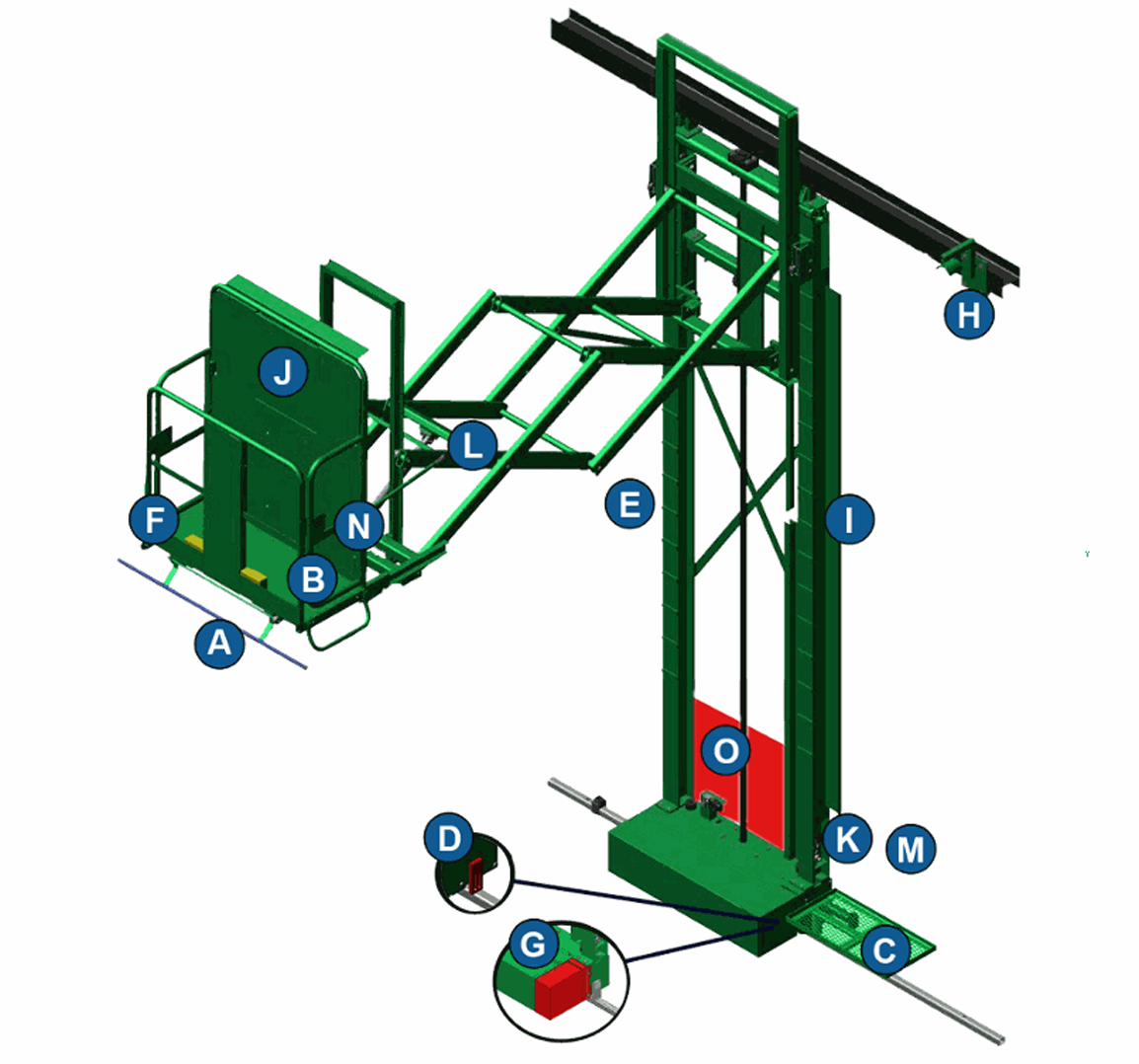

Features and Components

A) Bump Stop Control (optional)

A cushioned bumper that is mounted on the front of the basket. The lift automatically stops moving when the bumper contacts an object. A push button override switch located on the lift control panel can be actuated which will allow the lift basket to be moved away from the object it has contacted. This control will only activate on contact from the front of the basket. It will not activate on side impact or if the lift contacts an object while moving vertically up or down. This option is not easily added on the jobsite.

B) Basket Floor Material (optional)

Titan Air offers a diamond plate material or expanded metal for the basket floor. Expanded metal floor often requested for applications where it is important for air or water to flow through the basket floor.

C) Paint Pot Carrier (optional)

This option is used when the customer requires a paint pot to be located in the booth. The carrier can be built to carry a single 5 gallon paint pot or it can be made to carry two, 5 gallon paint pots. The carrier is attached to the lift base. Please note that this option will limit the access to one side of the lift basket when it is fully retracted. This option can be easily added on the jobsite.

D) Rail Scraper (optional)

An aluminum block used to help prevent the buildup of debris on the lower rail system. They are manually adjusted and can be easily added on the jobsite.

E) Custom Paint Color (optional)

Titan Air can custom paint your lift to match almost any color.

F) Foot Control (optional)

This option is typically used for the control of X-axis, (movement along the booth wall) which enables the operator to move the lift “hands free.” This option is not easily added on the jobsite.

G) Filter-Regulator- Lubricator

This filters, lubricates and regulates the main air supply going to the lift components.

H) Festoon Trolley

The standard lift has a trolley system that rolls along the top rail and carries the main air supply hose. These trolleys can be made to also carry paint and/or breathable air lines if requested.

I) Hose Containment Flex Track (optional)

This option is used for routing hoses from the lift mast out to the basket. Standard size is 1 inch by 4 inch ID. Larger sizes of flex track are available upon request. It is typically used to organize and contain breathing air lines, paint lines and/or other hoses. This option is easily added on the jobsite.

J) Emergency Stop Valve

This push / pull valve enables the operator to quickly stop air flow to the lift controls.

K) Mechanical Stop

The mechanical stops lock the basket to both vertical columns if the basket should suddenly drop.

L) Rollout Assembly (optional)

This option will enable the basket to extend an additional 21 inches. This option is typically used with a 3 axis lift but can be used on a 2 axis lift. The rollout assembly is automatically operated on a 3 axis lift and manually operated on a 2 axis lift. This option is not easily added on the jobsite.

M) Safety Lockout Valve

Rotating the valve handle 90° will shut off the air supply to the lift. This lockable valve will enable you to safely perform maintenance or repairs on the lift.

N) Inward Swinging Doors

This safety feature will help keep the operator inside the basket.

O) Filter Cover (optional)

This option is commonly used for side draft booth applications. It is a 48 inch tall sheet metal panel attached to the back of the lift columns. The panel blocks air from being pulled through the lift as it moves along the booth wall. This helps alleviate debris from accumulating on lift components such as the ballscrew. This option is not easily added on the jobsite.