Transportable Shipping Container Spray Booths

Marathon’s Portable Shipping Container Spray Booths convert ISO containers into fully compliant, high-performance finishing stations. Easy to set up, relocate, and maintain, these booths offer safety features, filtration systems, and reliable performance like permanent installations. Ideal for automotive, industrial, and commercial applications, they’re part of Marathon’s extensive spray booth product line.

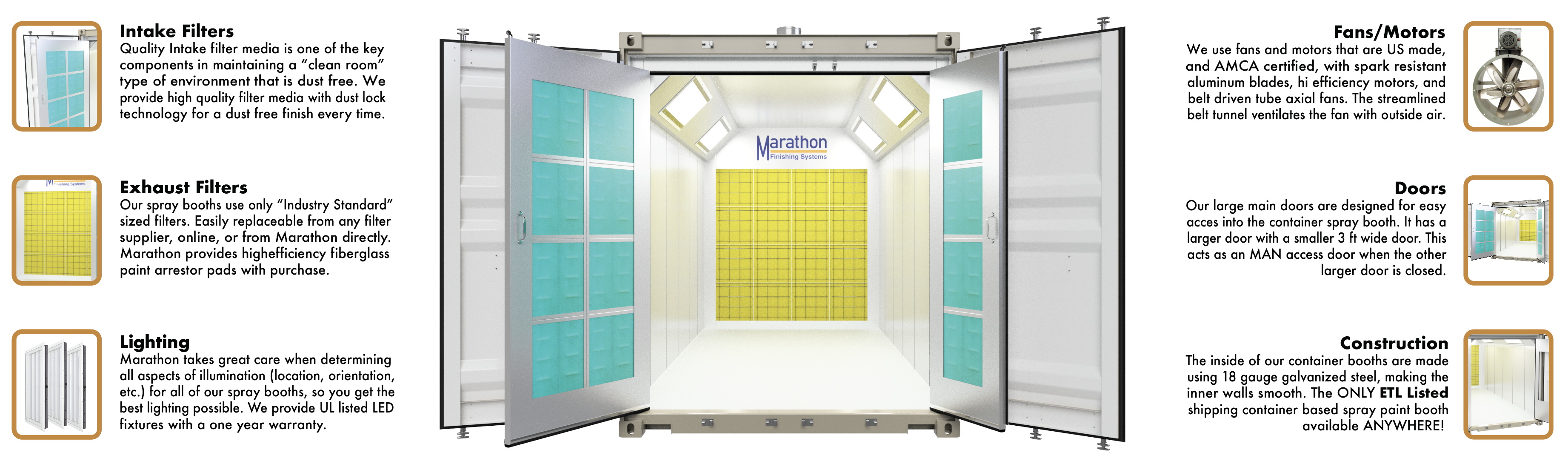

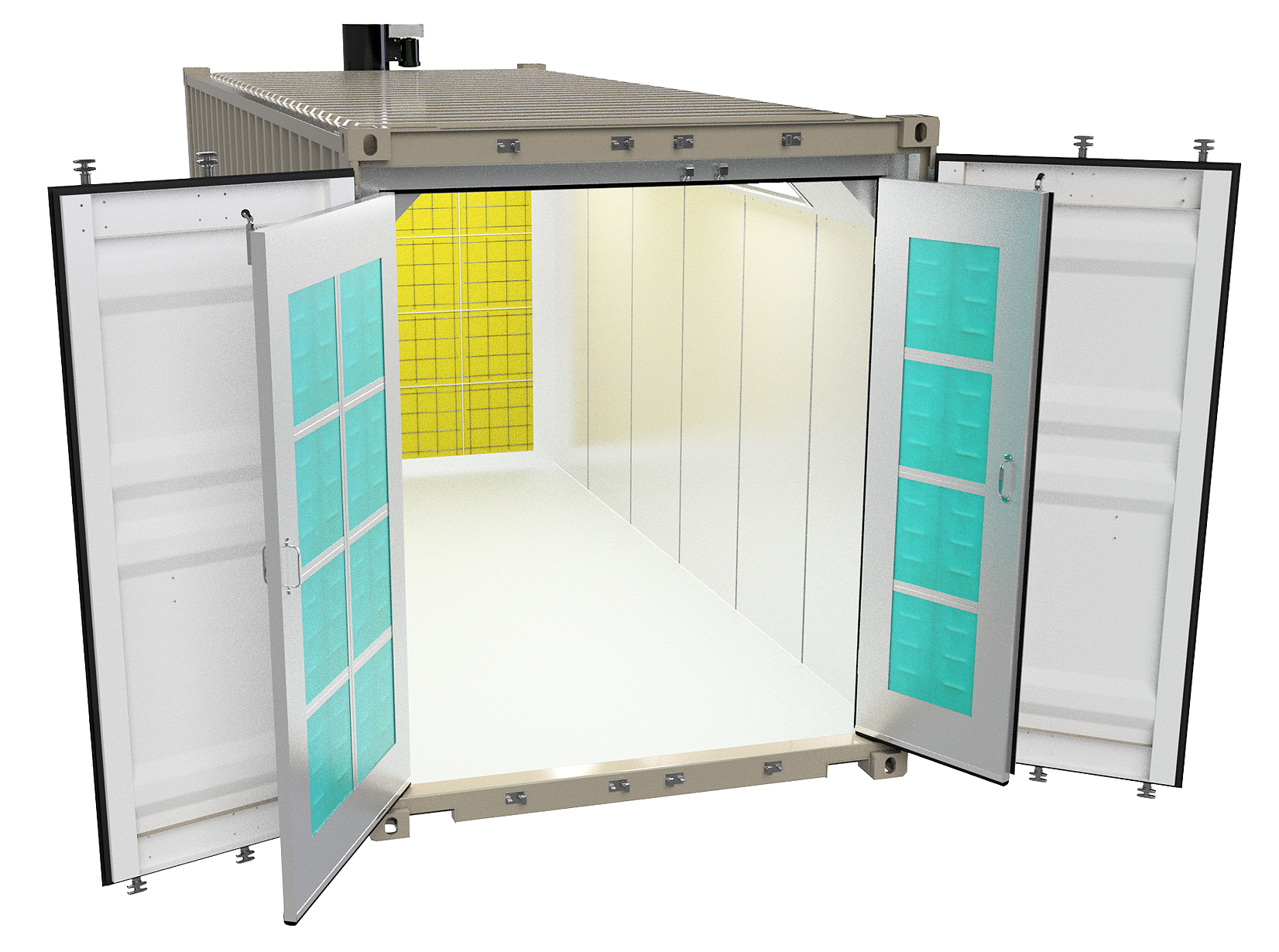

Our Container Spray Paint Booths are designed for maximum portability and straightforward operation. Configurable as an Open Face or Front Air Flow booth, it efficiently filters dust and particulates through the front door intake system—keeping your work environment clean and compliant. Ideal for outdoor or well-ventilated locations, it’s easy to relocate and maintain, making it perfect for businesses with evolving needs or limited indoor space.

Marathon Spray Paint Booths are ETL listed and comply with all applicable quality and safety standards.

Non Heated Container Spray Paint Booth

Heated Container Spray Paint Booth

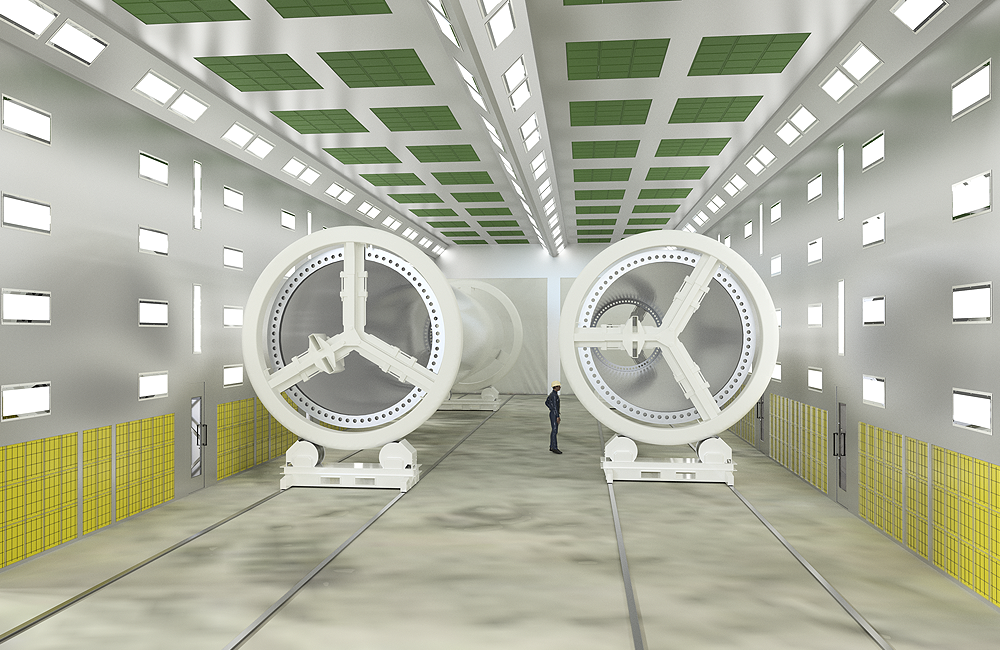

We Build Container Spray Booths in 20 ft or 40 ft Lengths

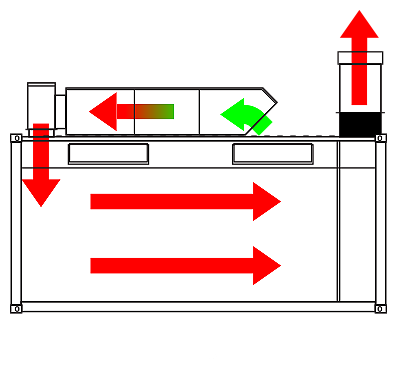

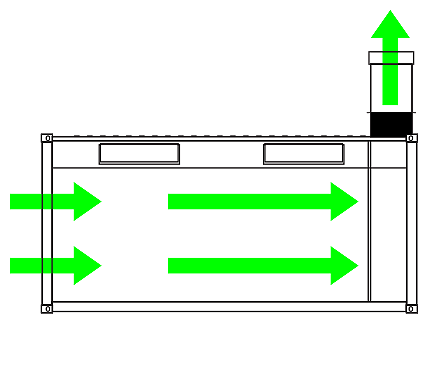

Airflow Key Features

Intake, Heated Booth:

Outside air is filtered twice, once as it enters in through the air make up unit located on top of the container booth, and again as it passes through the intake plenum filters (above the front doors). In this example this booth is equipped with a Spray & Cure heating unit, also known as ‘Make Up Air’.

Intake, Non Heated Booth:

Outside air is filtered once, through the front intake filter wall (front doors) before entering the work area.

Exhaust, Both Spray Booth Types:

The filtered air travels horizontally across the length of the booth (cross flow). Finally, the air is filtered of overspray and particulates by the exhaust filters before exiting the booth. Marathon uses standard size Intake and exhaust filter media, readily available from most paint and refinishing suppliers or directly from Marathon Finishing Systems.

Did you Know?

The ETL Listing (certification) is

confirmation that every aspect of

our construction meets or exceeds the

build and safety code standards established by

NFPA 33. This is important, as your Fire Inspector will require proof of compliance before approval.

Did you Know?

The ETL Listing (certification) is your confirmation that every aspect of our construction meets or exceeds the build and safety code standards established by NFPA 33. This is important, as your Fire Inspector will require proof of compliance before approval.

Industries Served

Automotive & Collision Repair

Marine & Boat Services

Aviation & Aerospace

Construction & Infrastructure

Military & Government

Industrial Manufacturing

FAQs

Do I need special permits for a mobile spray paint booth?

Most local regulations require compliance with NFPA 33 and local fire codes. Marathon’s booths meet these standards; however, always consult local authorities for specific permits.

Can the container booth be used outdoors?

Yes. These booths are designed to withstand various weather conditions, but additional accessories like protective canopies may be required in extreme climates

How do I switch from heated to non-heated configurations?

Our team can guide you through add-on or conversion kits. Heating units are typically mounted on top of the container for easy maintenance.