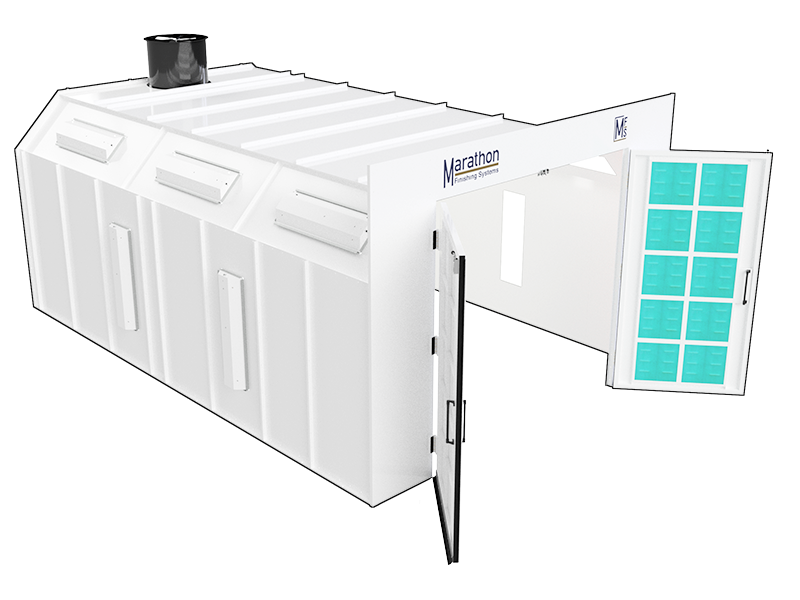

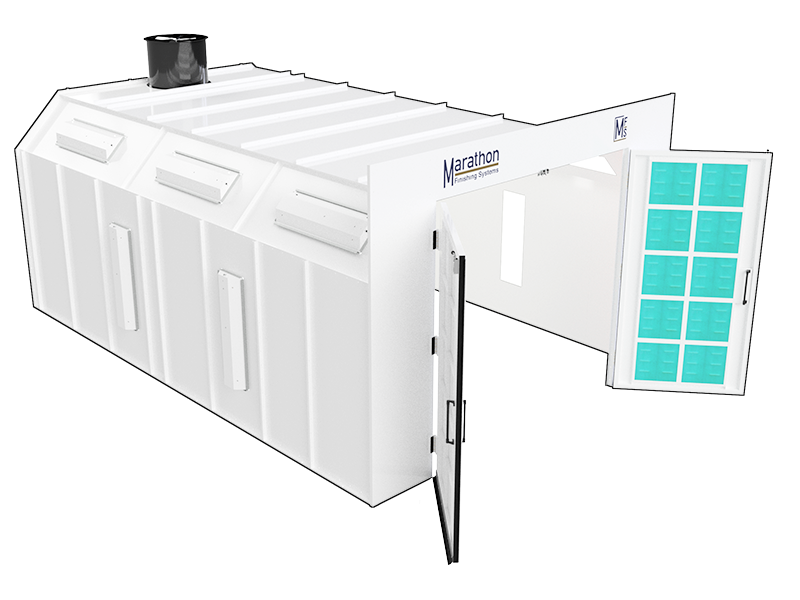

Truck & Equipment Spray Paint Booths – Outdoor Rated

Marathon’s line of Outdoor Rated Booths are designed to stand up to the harsh treatment from the weather. Rain, wind, sleet, and snow can take their toll on equipment that is not designed to take it. Our booths are structurally reinforced with strengthened joints, support beams, hinges and latches. Let Marathon show you the difference.

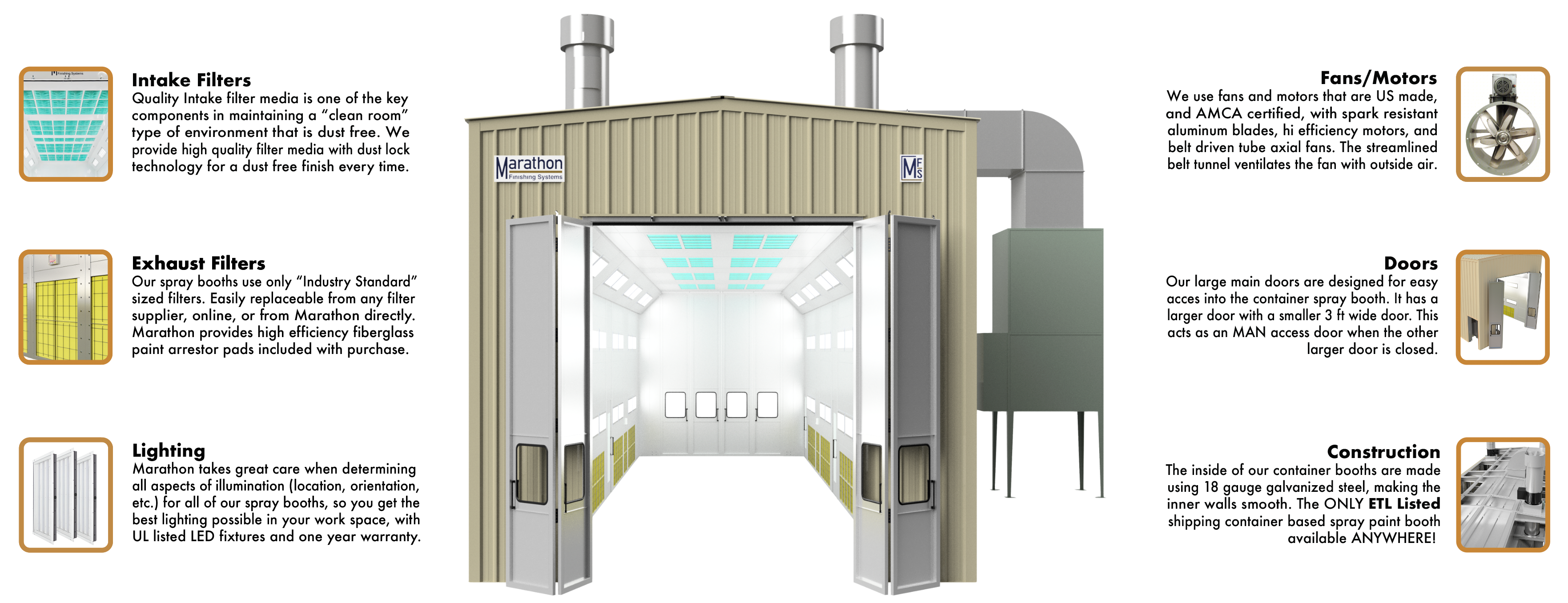

Marathon Spray Paint Booths are ETL listed and comply with all applicable quality and safety code standards.

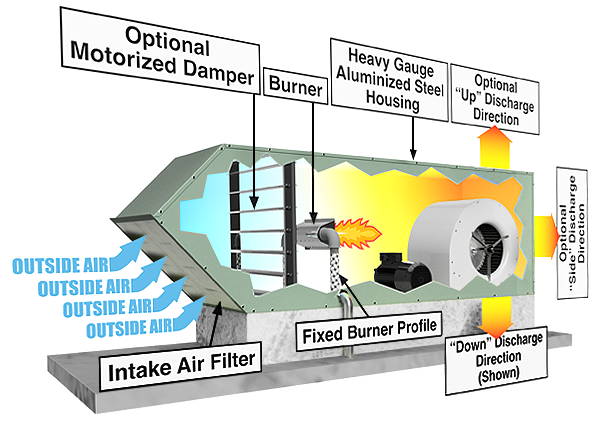

Heated Outdoor Rated Spray Paint Booth

Heated Outdoor Rated Spray Paint Booth

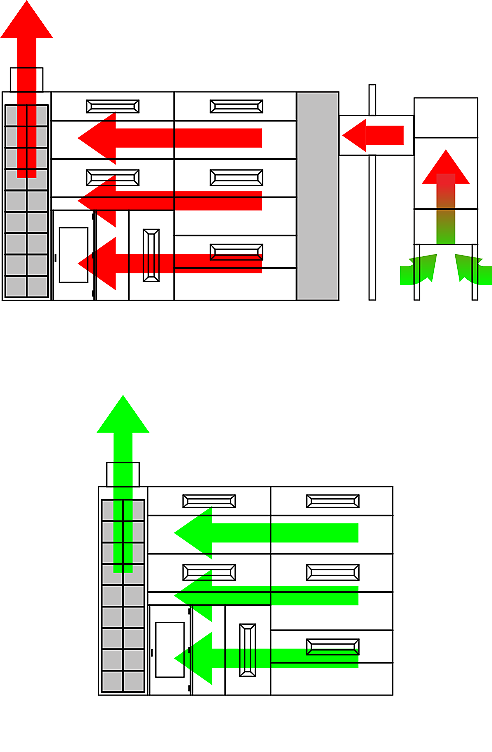

Truck & Large Equipment Outdoor Rated Air Flow Types

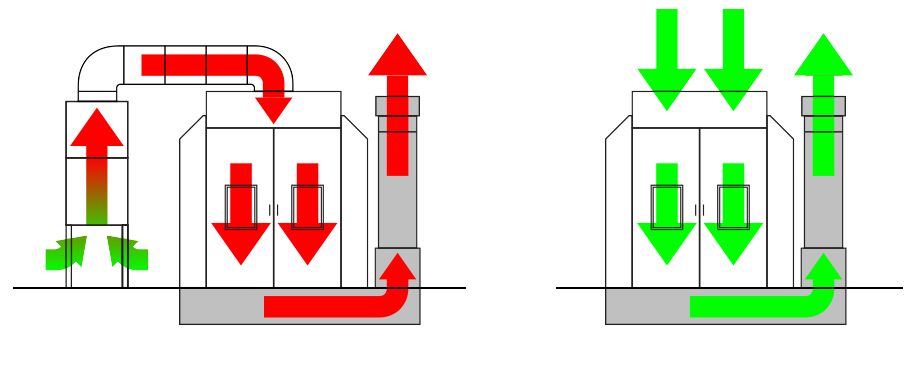

Full Down Draft – Heated

Intake:

Outside air is filtered twice, once as it enters in through the air make up unit (Heater) located next to (or on top of) the spray booth, and again as it passes through the intake plenum ceiling filters.

Exhaust:

Air moves vertically downwards (Down Draft), and picks up particulates. The contaminated air then travels through the pit in the floor, and is vented out through the exhaust ducting.

Full Down Draft – Non Heated

Intake:

Ambient air enters through the ceiling plenum and is filtered before it enters the work area.

Exhaust:

The filtered air travels vertically downward to the pit at the bottom of the booth (down draft). Finally, the air travels through the exhaust ducting and outside.

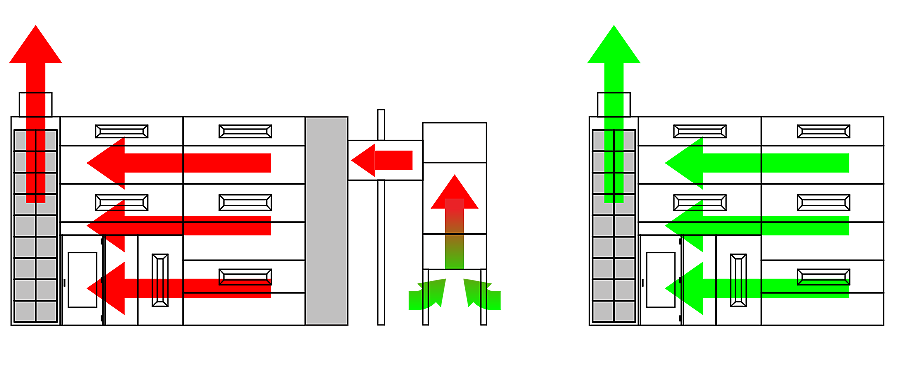

Reverse Air Flow – Heated

Intake:

Outside air is filtered twice, once as it enters in through the air make up unit (Heater) located behind the spray booth, and again as it passes through the rear intake filters.

Exhaust:

Air moves horizontally (Cross Flow) towards the front of the booth, and picks up particulates. The contaminated air then travels out through front exhaust plenums, and is ducted outside.

Reverse Air Flow – Non Heated

Intake:

Outside air is filtered as it enters the spray booth through the rear intake.

Exhaust:

Air moves horizontally (Cross Flow) towards the front of the booth, and picks up particulates. The contaminated air then travels out through front exhaust plenums, and ducted outside.

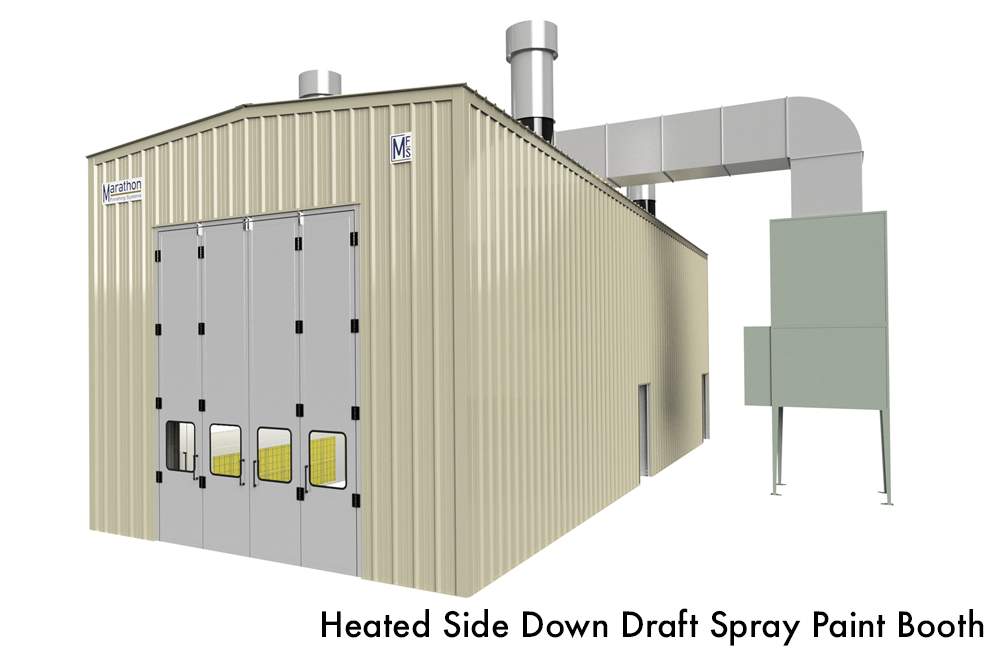

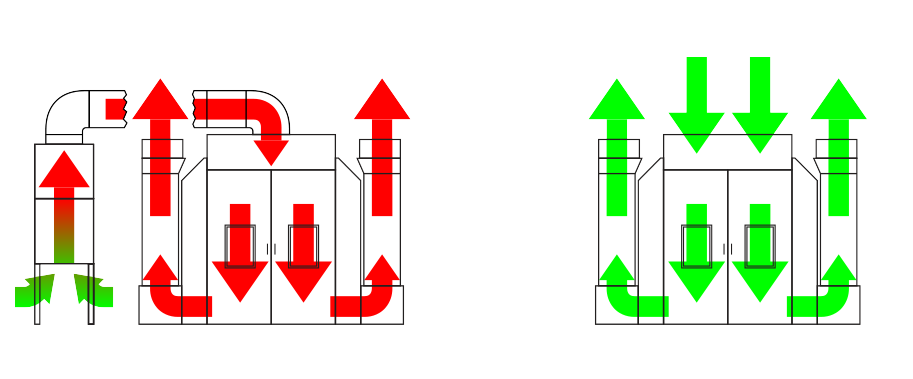

Side Down Draft – Heated

Intake:

Outside air is filtered twice, once as it enters in through the air make up unit (Heater) located next to (or on top of) the spray booth, and again as it passes through the intake plenum ceiling filters.

Exhaust:

Air moves vertically downwards (Down Draft), and picks up particulates. The contaminated air then travels to the floor level on the sides of the booth, and is vented out through the exhaust ducting.

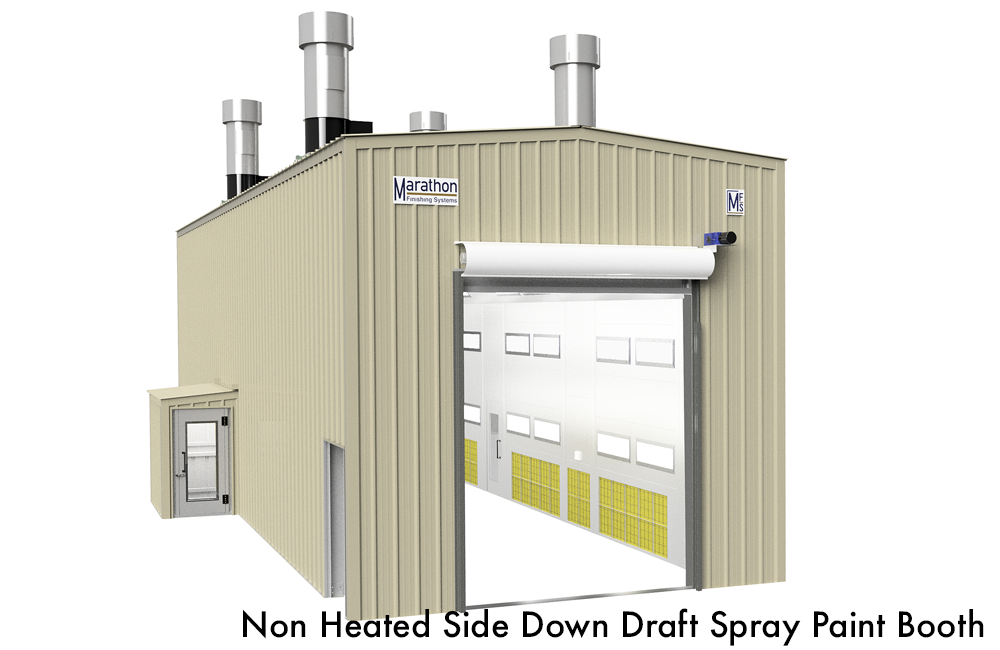

Side Down Draft – Non Heated

Intake:

Outside air is filtered as it enters in through the intake plenum ceiling filters.

Exhaust:

Air moves vertically downwards (Down Draft), and picks up particulates. The contaminated air then travels to the floor level on the sides of the booth, and is vented out through the exhaust ducting.

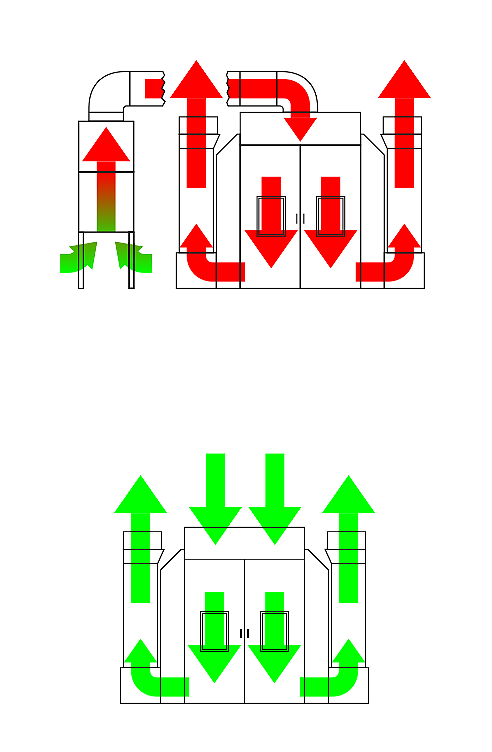

Truck & Large Equipment Outdoor Rated Air Flow Types

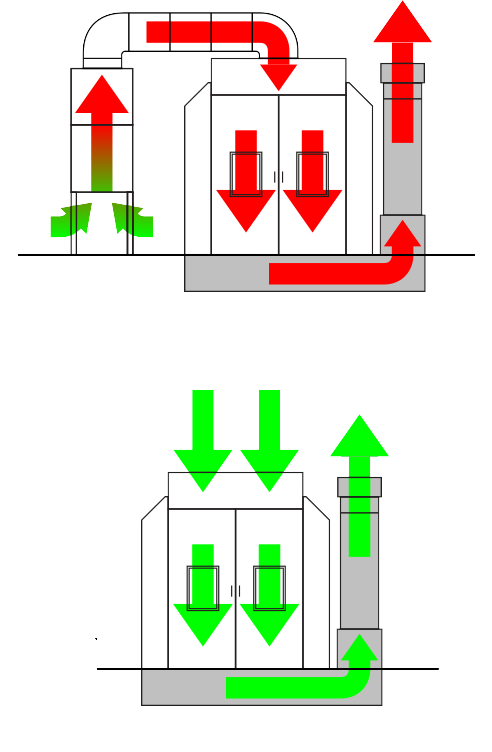

Full Down Draft – Heated

Intake:

Outside air is filtered twice, once as it enters in through the air make up unit (Heater) located next to (or on top of) the spray booth, and again as it passes through the intake plenum ceiling filters.

Exhaust:

Air moves vertically downwards (Down Draft), and picks up particulates. The contaminated air then travels through the pit in the floor, and is vented out through the exhaust ducting.

Reverse Air Flow – Heated

Intake:

Outside air is filtered twice, once as it enters in through the air make up unit (Heater) located behind the spray booth, and again as it passes through the rear intake filters.

Exhaust:

Air moves horizontally (Cross Flow) towards the front of the booth, and picks up particulates. The contaminated air then travels out through front exhaust plenums, and is ducted outside.

Side Down Draft – Heated

Intake:

Outside air is filtered twice, once as it enters in through the air make up unit (Heater) located next to (or on top of) the spray booth, and again as it passes through the intake plenum ceiling filters.

Exhaust:

Air moves vertically downwards (Down Draft), and picks up particulates. The contaminated air then travels to the floor level on the sides of the booth, and is vented out through the exhaust ducting.

Full Down Draft – Non Heated

Intake:

Ambient air enters through the ceiling plenum and is filtered before it enters the work area.

Exhaust:

The filtered air travels vertically downward to the pit at the bottom of the booth (down draft). Finally, the air travels through the exhaust ducting and outside.

Reverse Air Flow – Non Heated

Intake:

Outside air is filtered as it enters the spray booth through the rear intake.

Exhaust:

Air moves horizontally (Cross Flow) towards the front of the booth, and picks up particulates. The contaminated air then travels out through front exhaust plenums, and ducted outside.

Side Down Draft – Non Heated

Intake:

Outside air is filtered as it enters in through the intake plenum ceiling filters.

Exhaust:

Air moves vertically downwards (Down Draft), and picks up particulates. The contaminated air then travels to the floor level on the sides of the booth, and is vented out through the exhaust ducting.

Did you Know?

The ETL Listing (certification) is

confirmation that every aspect of

our construction meets or exceeds the

build and safety code standards established by

NFPA 33. This is important, as your Fire Inspector will require proof of compliance before approval.

Did you Know?

The ETL Listing (certification) is your confirmation that every aspect of our construction meets or exceeds the build and safety code standards established by NFPA 33. This is important, as your Fire Inspector will require proof of compliance before approval.

We Also Build Custom Sizes and Configurations, Just Ask!

Available Options for This Booth Type to Consider

Powder Coating

Clean, beautiful, Bright White Powder Coating. Inside and outside, the entire booth!

Additional Filters

Don’t get caught off guard! Make sure you have enough filters on hand by ordering extra filters.

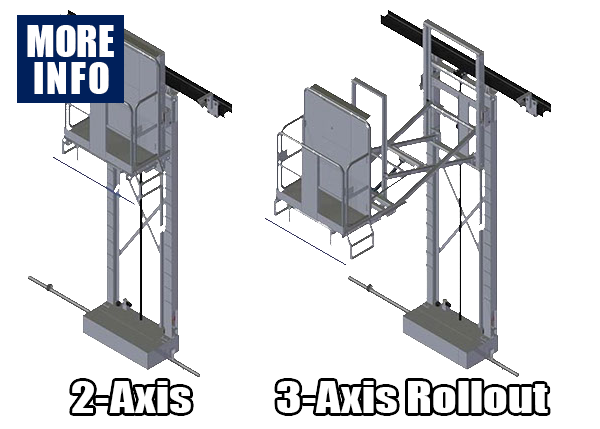

Personnel Lifts

We offer Personnel (Man) Lifts for effectively painting large items with enhanced safely.

Drive/Pass Thru Doors

Streamline your production loop. Integrates with existing automated production lines.

Paint Mixing Rooms

Don’t forget a paint mixing room. An important addition to your painting operation.

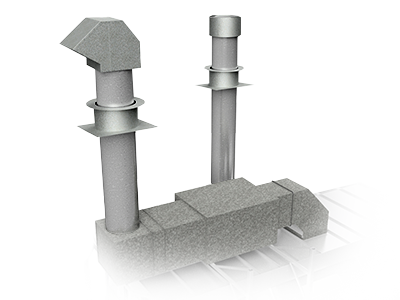

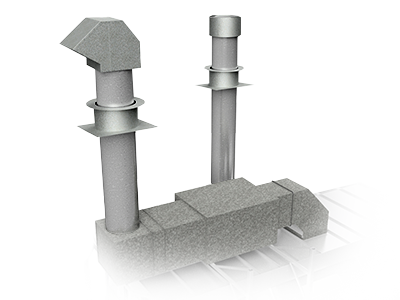

Ducting Options

Whether it’s a short run, or an entire facility air flow system, we have what you need.

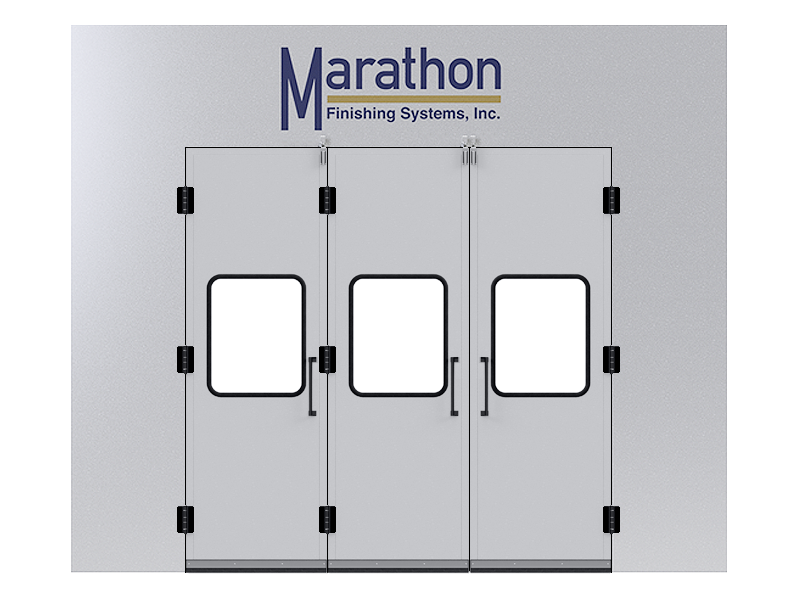

Tri-Fold Doors

3 doors ( 2 on the left, 1 on the right). 2″ tube frame, single skin, with viewing windows

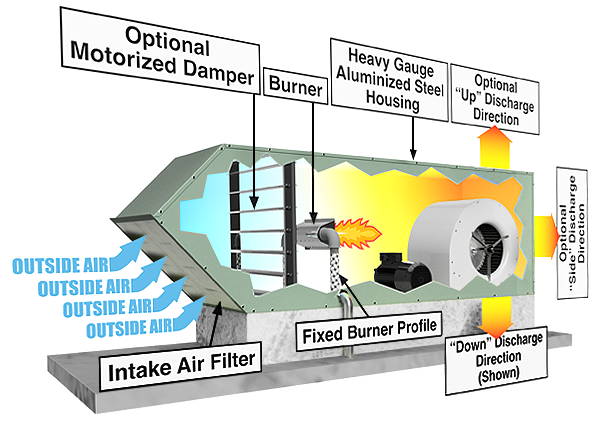

Spray & Cure Heat

Add a heating system to increase quality and and decrease turn around times.

Bi-Fold (Quad) Doors

4 doors (2 left, 2 right) that open out from center. 2″ tube frame, single skin, with windows.

Personnel Lifts

We offer Personnel (Man) Lifts for effectively painting large items with enhanced safely.

LED Lighting Fixtures

We offer many different styles and types of lighting fixtures to offer for your spray paint booth.

Roll-Up Doors

Standard roll-up door with hard vinyl slats. Available in many colors and configurations.

Booth Coat

You’ve spent a lot of money on your spray paint booth, so you should protect it. Clear or White.

RollSeal Roll-Up Doors

A non-rigid alternative to a standard roll-up door. Sizes from 8ft x 8ft to 14ft x 14ft.

Available Options for This Booth Type to Consider

Powder Coating

Clean, beautiful, Bright White Powder Coating. Inside and outside, the entire booth!

Drive/Pass Thru Doors

Streamline your production loop. Integrates with existing automated production lines.

Ducting Options

Whether it’s a short run, or an entire facility air flow system, we have what you need.

Spray & Cure Heat

Add a heating system to increase quality and and decrease turn around times.

LED Lighting Fixtures

We offer many different styles and types of lighting fixtures to offer for your spray paint booth.

Booth Coat

You’ve spent a lot of money on your spray paint booth, so you should protect it. Clear or White.

Additional Filters

Don’t get caught off guard! Make sure you have enough filters on hand by ordering extra filters.

Paint Mixing Rooms

Don’t forget a paint mixing room. An important addition to your painting operation.

Tri-Fold Doors

3 doors ( 2 on the left, 1 on the right). 2″ tube frame, single skin, with viewing windows

Bi-Fold (Quad) Doors

4 doors (2 left, 2 right) that open out from center. 2″ tube frame, single skin, with windows.

Roll-Up Doors

Standard roll-up door with hard vinyl slats. Available in many colors and configurations.

RollSeal Roll-Up Doors

A non-rigid alternative to a standard roll-up door. Sizes from 8ft x 8ft to 14ft x 14ft.

Personnel Lifts

We offer Personnel (Man) Lifts for effectively painting large items with enhanced safely.