Grinding & Sanding Booths

Marathon Finishing Systems, Inc. specializes in the engineering, manufacture, and installation of industrial spray paint booths, blasting & grinding booths, mixing rooms, service bays, and specialized finishing systems. Our products are used for surface preparation, coating, painting, and finishing applications by virtually every segment of industrial production and manufacturing where high quality finishing is required. We also provide full “Start Up” and training after installation.

Marathon Products are ETL listed

and comply with all applicable

quality and safety standards.

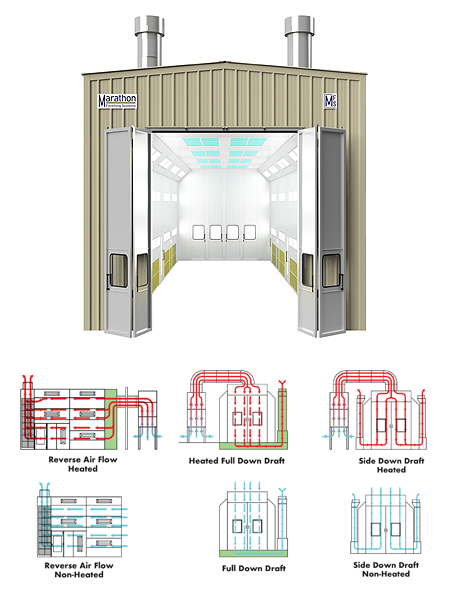

Outdoor Rated

Outdoor Rated booths can be built as:

- Reverse Air Flow

- Full Down Draft

- Side Down Draft

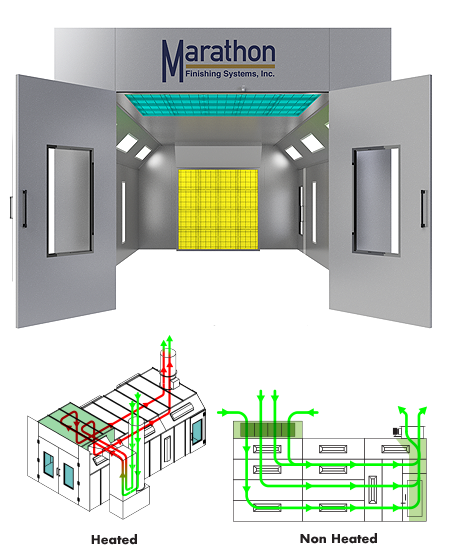

Modified Down Draft

Also known as a Semi Down Draft. Designed to be an efficient, lower cost, & high finish quality Cross Flow booth. Easy to operate and maintain. Custom design and heated options available.

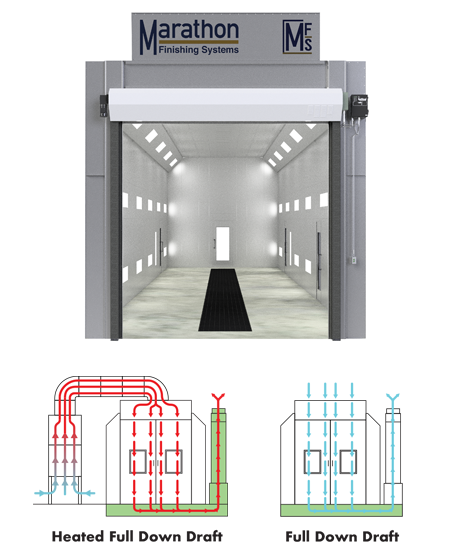

Full Down Draft

A pure down draft spray paint booth, with an exhaust pit built into the floor of the booth. Standard models or custom design. This style can be ordered with a Spray & Cure Air Makeup heating unit.

Front Air Flow

A pure Cross Flow spray paint booth. Air enters through the front door filters, travels to the rear exhaust filter plenum, and is ducted out. This design can NOT have a Spray & Cure heating option.

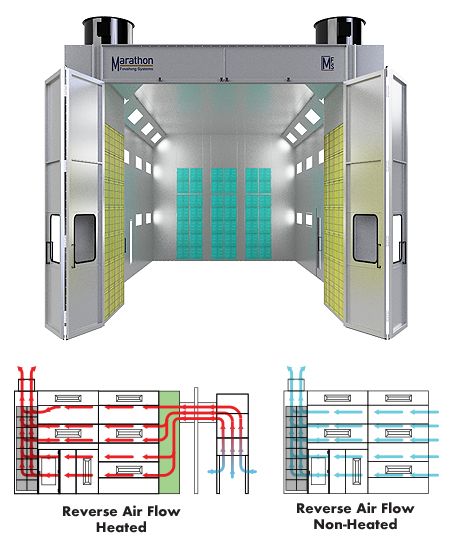

Reverse Air Flow

This spray paint booth design has air enter the booth at the rear, travel horizontally (Cross Flow) to the front, where it is ducted out. Custom design and heated options available.

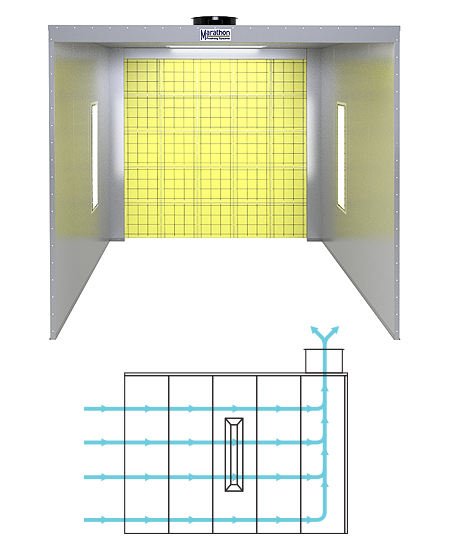

Industrial Open Face

A Cross Flow design, similar to the Front Air Flow, without the filtered front doors. Great for mid sized components and small runs! This design can NOT have a Spray & Cure heating option.

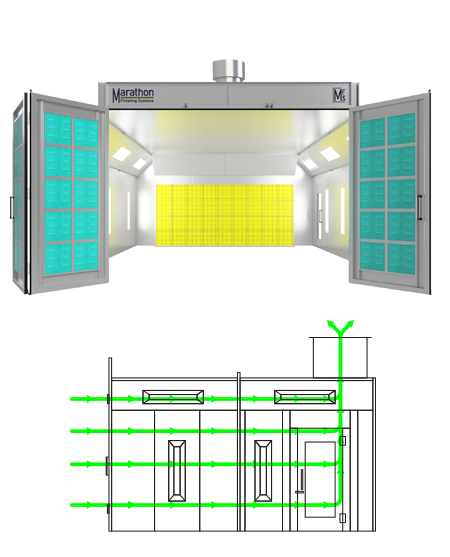

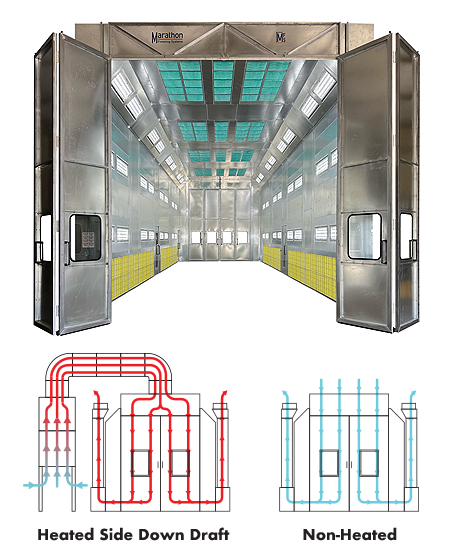

Side Down Draft

A Down Draft without the cost of a pit. Air comes in through the top, flows down to the bottom exhausts on each side, and ducted out. Custom design and heated options available.

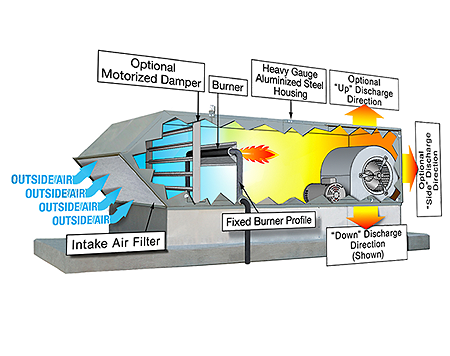

Air Make Up Spray & Cure Heat

Energy efficient heating and curing systems found here! Do you need to add a Spray & Cure Heat System to your new spray booth order, or add one to your existing spray booth? Heat curing provides you and your customers with the best, most durable finish you can get. Are you are working with Waterborne paints? Marathon Finishing can provide you with the best heating, curing, and drying units in the industry, even if you already have a booth.

Sandblasting Booths for Automotive Components

When you need to remove rust, paint, or other pernicious substances from the surface of a vehicle or automotive component, you’ll need to use sandblasting equipment you can trust. Learn more about the art of sandblasting and why a Marathon sandblasting booth is the ideal solution for your sandblasting needs.

What Is Sandblasting?

Sandblasting is the process of using a granular, sand-like substance to remove unwanted materials from the surface of a metal or otherwise significantly hard surface. The sand-like substances used in sandblasting are called abrasives, and they can be made from materials like glass, silicon carbide, aluminum oxide, steel grit, and plastic.

A variety of different types of technologies can be used to propel sand at an object at high speeds, but certain technologies are better than others. Sandblasting is a relatively dangerous endeavor, and it’s best to take full precautions by performing this task in a completely enclosed environment.

What Is a Sandblasting Booth?

A sandblasting booth is an enclosed structure that has been hooked up to a device that shoots sand into the booth from one or more inlets. These booths can be made to accommodate any size of vehicle or automotive part, and they feature the ventilation necessary to keep sandblasting safe and effective.

Marathon sandblasting booths can be made in any custom size that you desire, and outside air is filtered twice before it enters one of these booths. This filtered air passes along the bottom of the booth before it is filtered as it exits the booth.

Sandblasting booths are the safest types of sandblasting equipment since they provide fully enclosed spaces. These pieces of sandblasting equipment are also the most effective tools for sandblasting entire vehicles or large automotive components like transmissions.

Popular Sandblasting Booth Uses

Here are a few of the most common uses for sandblasting booths like those we offer at Marathon:

-

Cleaning of Engine Components

A variety of engine components can be affected by rust and other forms of corrosion. In many cases, sandblasting is the most effective technique for removing corrosion, dirt, or other unwanted coatings from gearboxes, connecting rods, and transmissions. This technique can also be used to remove sand from brake shoes and clutches.

-

Cleaning of Chassis Components

As vehicles age, their underbody components can become covered with rust, dirt, and other coatings that reduce their performance and eventually lead to component breakdown. Sandblasting techniques like shot peening, which uses metal particles, can be used to remove corrosion from stabilizing bars, springs, axles, and a variety of other automotive components that are routinely exposed to wet conditions.

-

Preparation of Car Wheels

Before car wheels can be equipped with tires and mounted onto vehicles, it’s often necessary to clean these wheels with sandblasting or similar techniques. Old wheels that have become dirty or covered with corrosion can be prepared for painting with sandblasting, and this process may also be performed on newer wheels.

-

Descaling of Screws

It’s sometimes necessary to put special types of coatings on components before they can be used in automotive and other heavy-duty applications. To prepare components for these coatings, a process called descaling is often warranted, which involves the use of sandblasting to remove the outer layer of heavy-duty components.

-

Removing Paint from Car Bodies

One of the most common uses of sandblasting is the removal of paint from the body of an automobile. While removal of paint isn’t always necessary before performing a new paint job, doing so can make a new paint job look more natural and avoid any unsightly color contrasts in the event of paint scratching.

Sandblasting is uniquely useful in the removal of paint from the body of a vehicle. While other paint removal techniques take a long time or expose workers to toxic chemicals, sandblasting neatly removes all of the paint from a vehicle with no potential of workplace hazards.

During the process of sandblasting to remove paint, other issues, such as the presence of rust or dirt, can be addressed. This multipurpose technique makes sandblasting booths highly popular among auto body shops around the world.

Get a Custom USA-Made Sandblasting Booth from Marathon Spray Booths

Whatever surface you need to sandblast, we have a solution for you. Here at Marathon Spray Booths, we make custom grinding and sandblasting booths that are designed to work with any type of industrial setting. All of our booths are made in the USA, and we can produce booths that are portable or stackable based on your needs. To learn more about how a sandblasting booth from Marathon can take your business to the next level, give us a call at 310.791.5601 today.