Industrial Finishing Spray Paint Booths – Front Air Flow

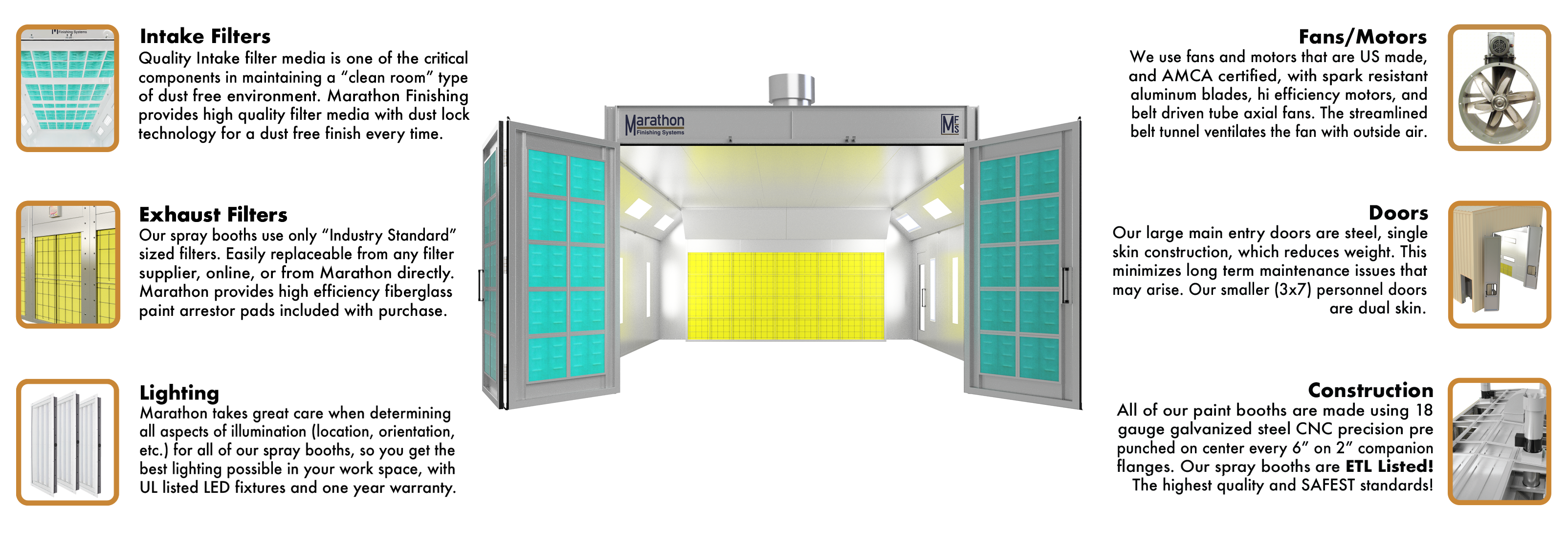

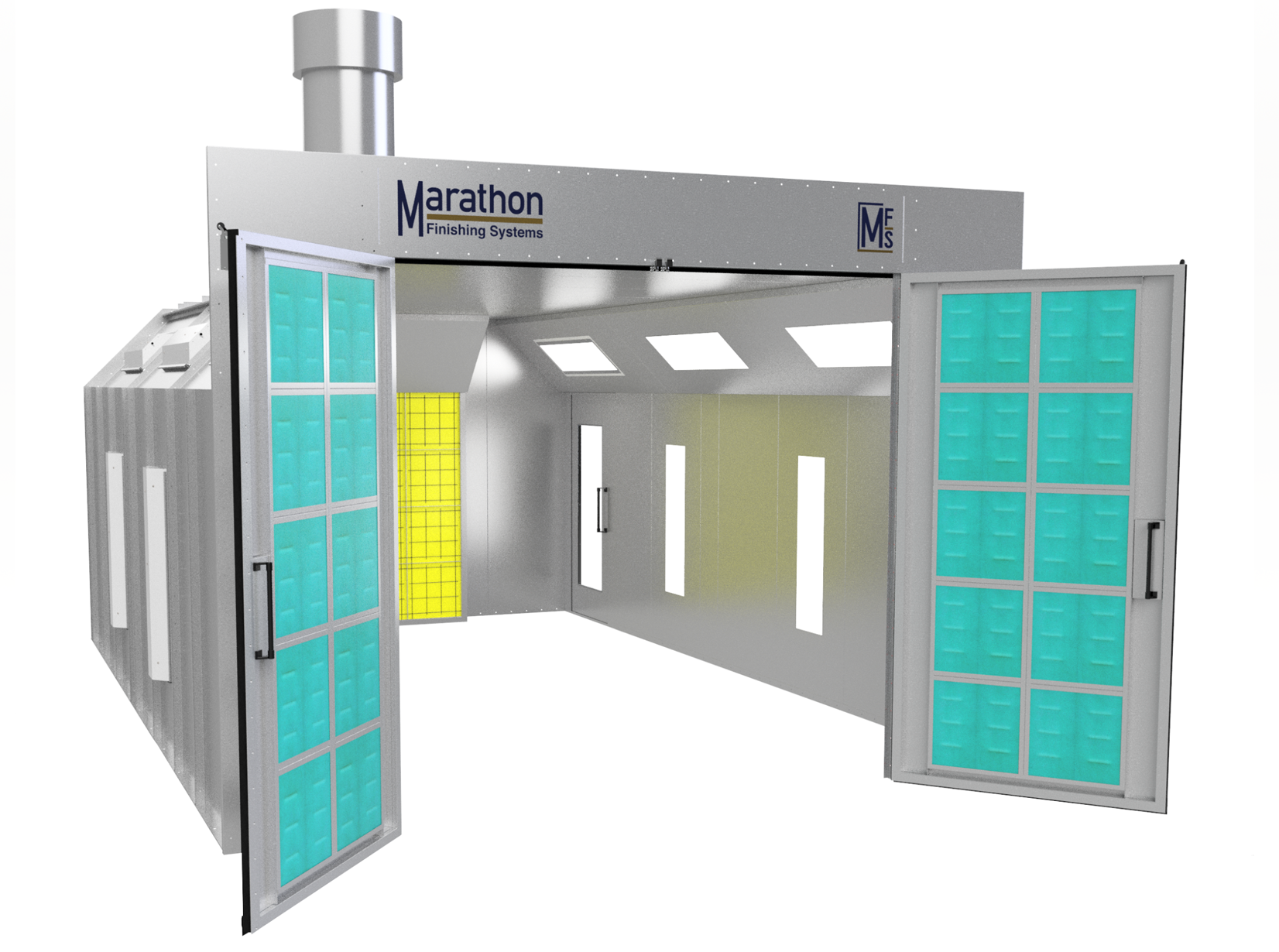

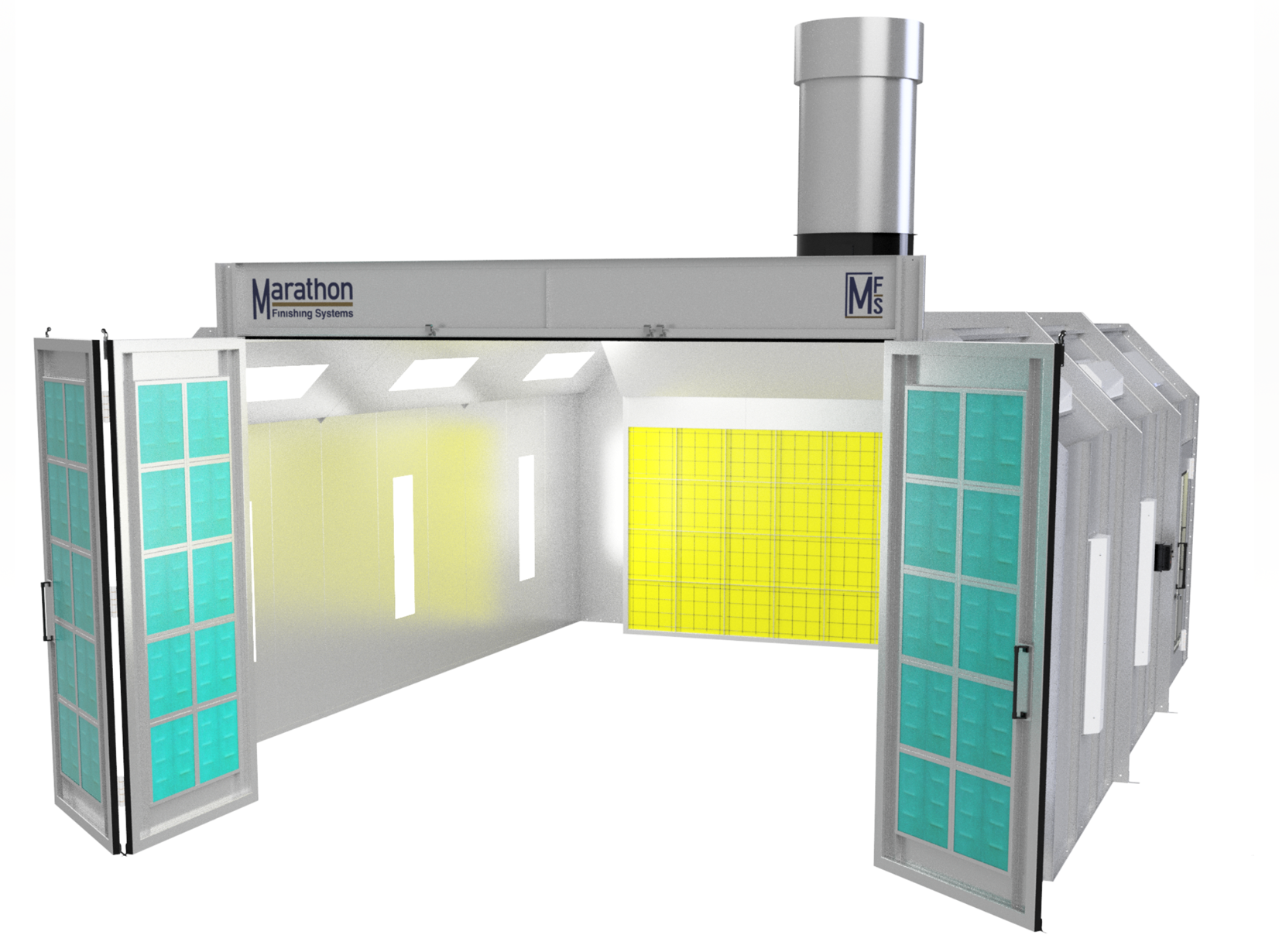

Marathon’s Automotive Front Air Flow Spray Paint Booths are designed to be an affordable finishing solution when starting up a new business, without sacrificing quality. The Front Air Flow is a great all around spray booth for spraying anything from vehicles to large equipment, and a very popular model. This booth type can NOT have a heating unit added.

listed and comply with all applicable

quality and safety standards.

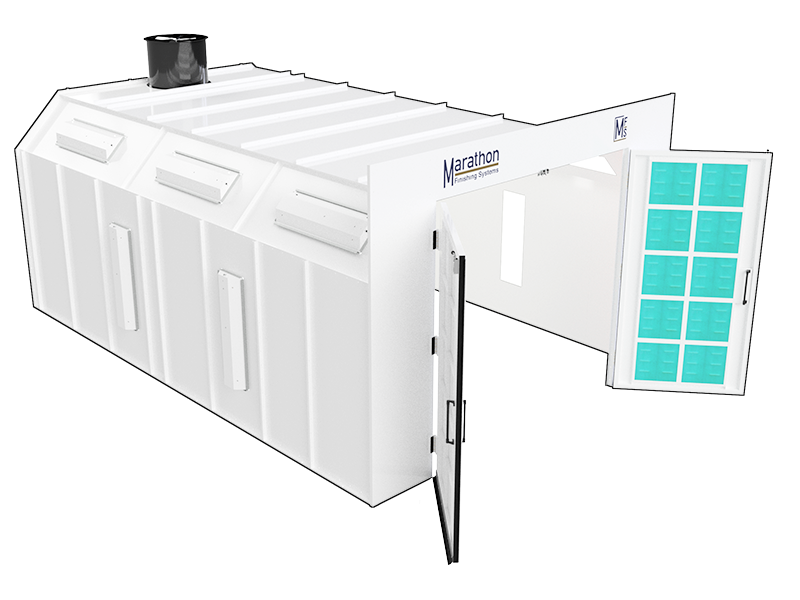

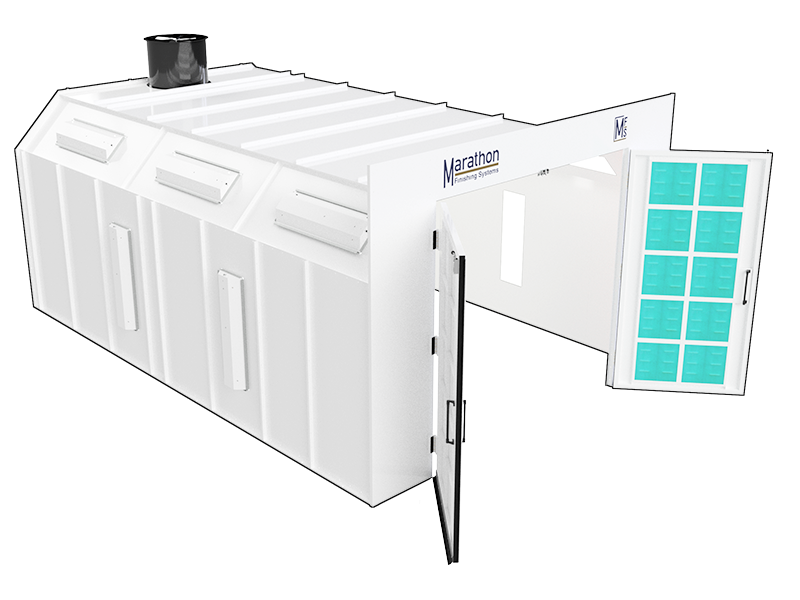

Non Heated Front Air Flow Paint Booth

Non Heated Front Air Flow Spray Paint Booth

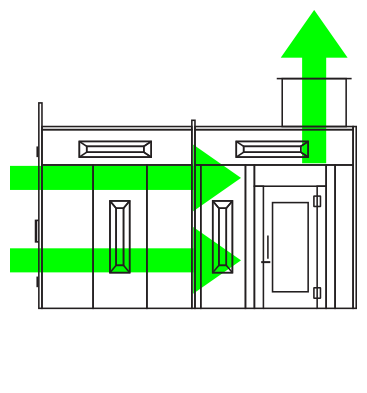

Air Flow – Front Air Flow Spray Paint Booth

Ambient (surrounding environment) air is pulled in through the filters at the front of the spray booth, flows horizontally across the booth (cross Flow), and is exhausted up and out of the booth.

Because of the simple, “In-Door Filter” design of this spray paint booth, heating the incoming air CAN be done, it is usually cost prohibitive to do so.

Did you Know?

The ETL Listing (certification) is

confirmation that every aspect of

our construction meets or exceeds the

build and safety code standards established by

NFPA 33. This is important, as your Fire Inspector will require proof of compliance before approval.

Did you Know?

The ETL Listing (certification) is your confirmation that every aspect of our construction meets or exceeds the build and safety code standards established by NFPA 33. This is important, as your Fire Inspector will require proof of compliance before approval.

Available Options for This Booth Type to Consider

Powder Coating

Clean, beautiful, Bright White Powder Coating. Inside and outside, the entire booth!

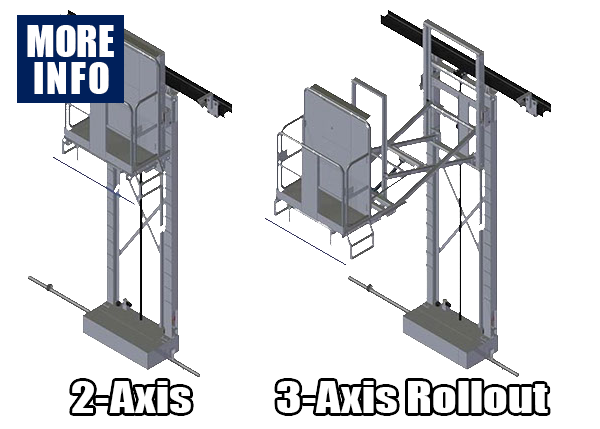

Personnel Lifts

We offer Personnel (Man) Lifts for effectively painting large items with enhanced safely.

Paint Mixing Rooms

Don’t forget a paint mixing room. An important addition to your painting operation.

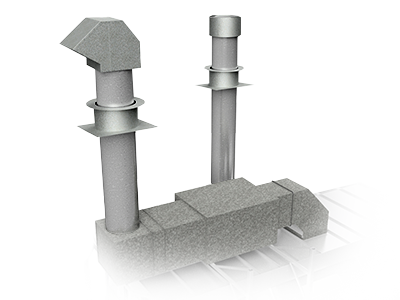

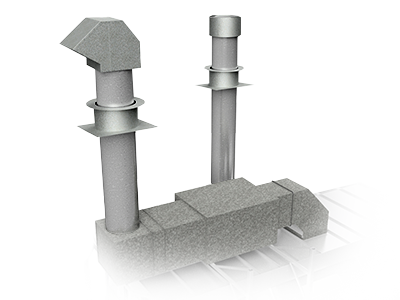

Ducting Options

Whether it’s a short run, or an entire facility air flow system, we have what you need.

Additional Filters

Don’t get caught off guard! Make sure you have enough filters on hand by ordering extra filters.

Personnel Lifts

We offer Personnel (Man) Lifts for effectively painting large items with enhanced safely.

LED Lighting Fixtures

We offer many different styles and types of lighting fixtures to offer for your spray paint booth.

Booth Coat

You’ve spent a lot of money on your spray paint booth, so you should protect it. Clear or White.

Available Options for This Booth Type to Consider

Powder Coating

Clean, beautiful, Bright White Powder Coating. Inside and outside, the entire booth!

Paint Mixing Rooms

Don’t forget a paint mixing room. An important addition to your painting operation.

Ducting Options

Whether it’s a short run, or an entire facility air flow system, we have what you need.

Additional Filters

Don’t get caught off guard! Make sure you have enough filters on hand by ordering extra filters.

LED Lighting Fixtures

We offer many different styles and types of lighting fixtures to offer for your spray paint booth.

Booth Coat

You’ve spent a lot of money on your spray paint booth, so you should protect it. Clear or White.

Personnel Lifts

We offer Personnel (Man) Lifts for effectively painting large items with enhanced safely.