Grinding Booths

Prep and finishing work is messy business, and keeping particulates from contaminating your environment is a mandatory requirement. Worker safety and product quality can be adversely affected when air quality is not properly established and maintained, and as a business owner, the liability is on you. Marathon’s automotive and other grinding/sanding booths are critical to establishing an “isolated environment” that will not only segregate high particulate work areas, but allow you to provide a safe work environment within those segregated zones, and give you full control over the waste products generated during the production cycle.

Marathon Products are ETL listed

and comply with all applicable

quality and safety standards.

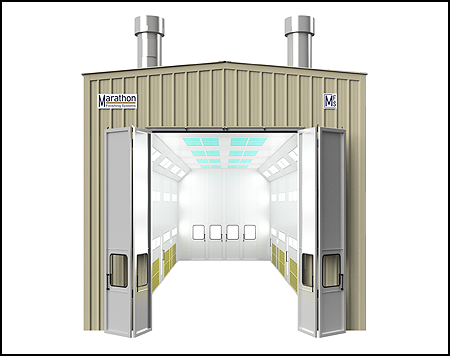

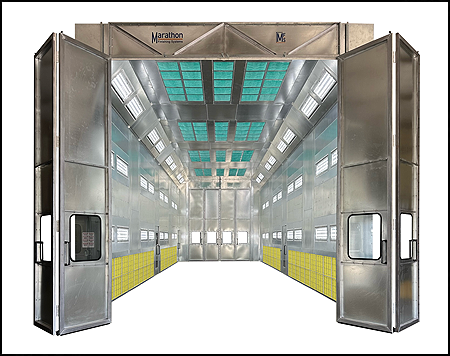

Outdoor Rated

Marathon’s Outdoor Rated Spray Booth with integrated covers, steel re-enforced structure and heavy duty components are built to withstand weather that would otherwise prevent operations! No protective building required! Can be ordered with Spray & Cure heat.

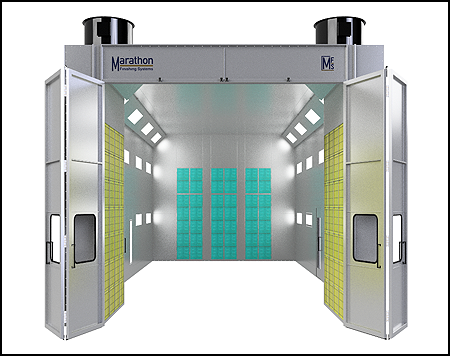

Modified Down Draft

Also known as a Semi Down Draft Spray Paint Booth, this model is designed to be an efficient finishing solution, an excellent balance between lower cost, high finish quality and ease of use. This model can be ordered with the Spray & Cure heater option.

Full Down Draft

Marathon’s Full Down Draft Spray Paint Booths are designed to be the absolute best spray production finishing solution. A pure down draft, it is considered by many to be the superior spray booth air flow type. Can an be ordered with a Spray & Cure heater.

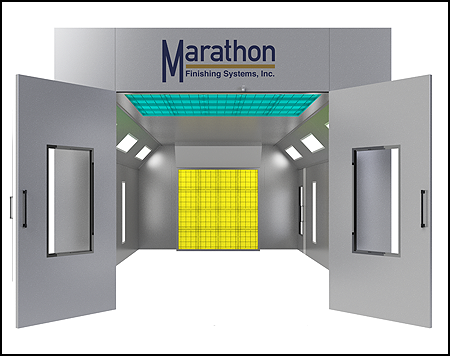

Front Air Flow

Marathon’s Front Air Flow Spray Paint Booths are designed to be an affordable finishing solution when starting up a new business, without sacrificing quality. This booth’s design makes it a great, “All Around” spray booth. This design can NOT have a Heating/Curing unit.

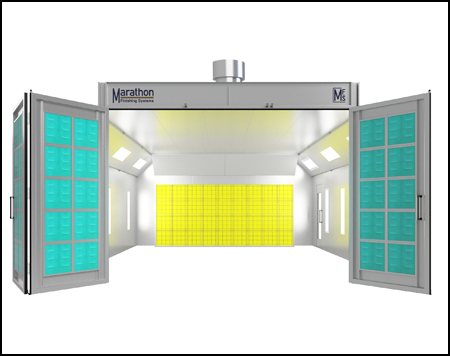

Reverse Air Flow

Marathon’s Reverse Air Flow Spray Paint Booths are designed to be a clean and efficient spray painting production solution that can enhance any finishing job, with the highest quality paint finish. This model of spray booths can be ordered with a Spray & Cure heater.

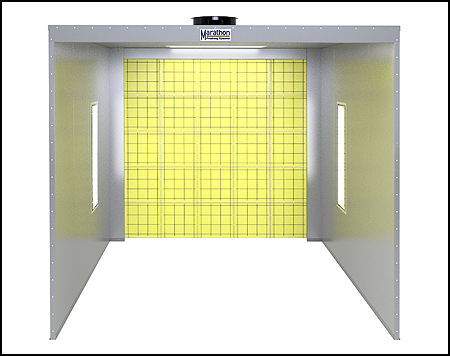

Industrial Open Face

As an Industrial paint booth manufacturer, we engineer our Open Face Spray Paint Booths to exceed your expectations! If you need a large or small booth, or anything in between, we provide a rugged, heavy duty product. This booth type can NOT have a Heating/Curing unit.

Side Down Draft

Marathon’s Side Down Draft Spray Paint Booths are designed to be a premium finishing solution for high-end production environment. A Down Draft Paint Booth, but without the cost of having to build a sub-floor or “Pit”. This model can be ordered with Spray & Cure Heat.

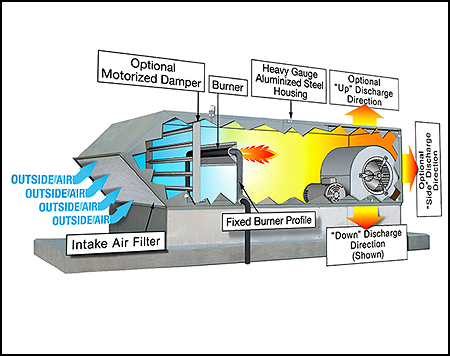

AMU/Spray & Cure Heat

Fuel efficient systems found here! Do you need to add a Spray & Cure Heat System to your new spray booth order, or add one to your existing spray booth? Are you are working with Waterborne paints? We provide the best heating, curing, and drying units in the industry.