Sand Blasting Booths

Marathon’s Sandblasting Booths are built for doing dirty, dusty work, and keeping particulates from contaminating your environment is a mandatory requirement. Worker safety and product quality can be adversely affected when air quality is not properly established and maintained, and as a business owner, the liability is on you.

Marathon’s blasting booths are critical to establishing an “isolated environment” that will not only segregate high particulate work areas, but allow you to provide a safe work environment within those segregated zones, and give you full control over the waste products generated during the production cycle.

Marathon Products are ETL listed

and comply with all applicable

quality and safety standards.

Booth Types

Outdoor Rated

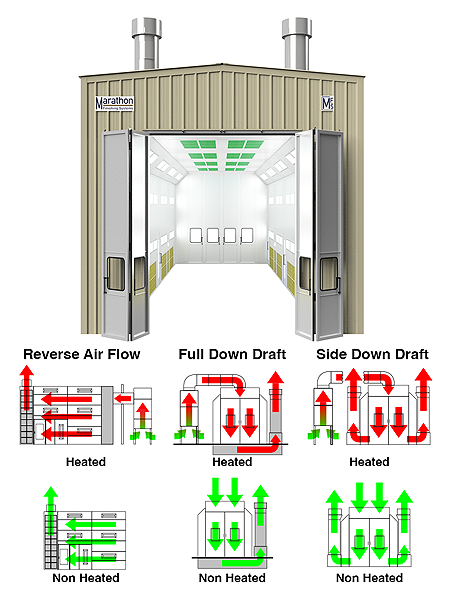

Outdoor spray paint booths can be configured as:

- Full Down Draft

- Reverse Air Flow

- Side Down Draft

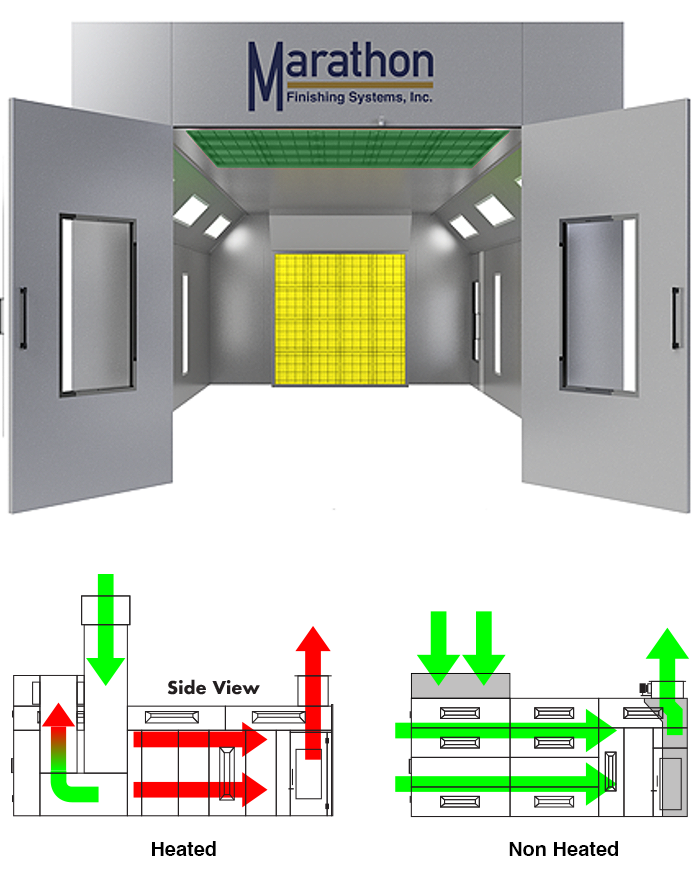

Full Down Draft

A pure down draft spray paint booth, with an exhaust pit built into the floor of the booth. Standard models or custom design. This style can be ordered with Spray & Cure Air Makeup heating.

Reverse Air Flow

This spray paint booth design has air enter the booth at the rear, travel horizontally (Cross Flow) to the front, where it is ducted out. Custom design and heated options available.

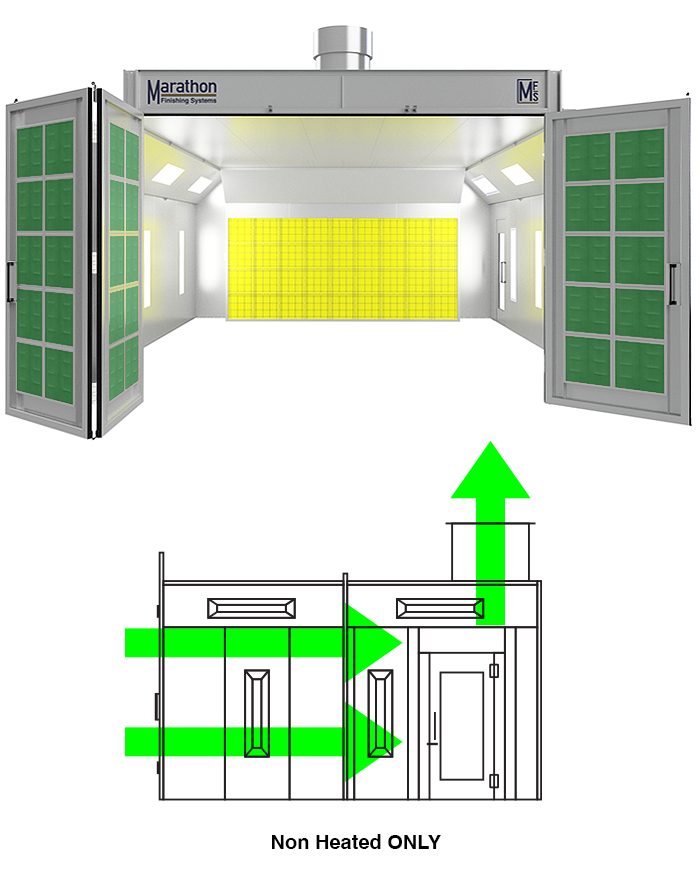

Side Down Draft

A Down Draft without the cost of a pit. Air comes in through the top, flows down to the bottom exhausts on each side, and ducted out. Custom design and heated options available.

Modified Down Draft

Also known as a Semi Down Draft. Designed to be an efficient, lower cost, & high finish quality Cross Flow booth. Easy to operate and maintain. Custom design and heated options available.

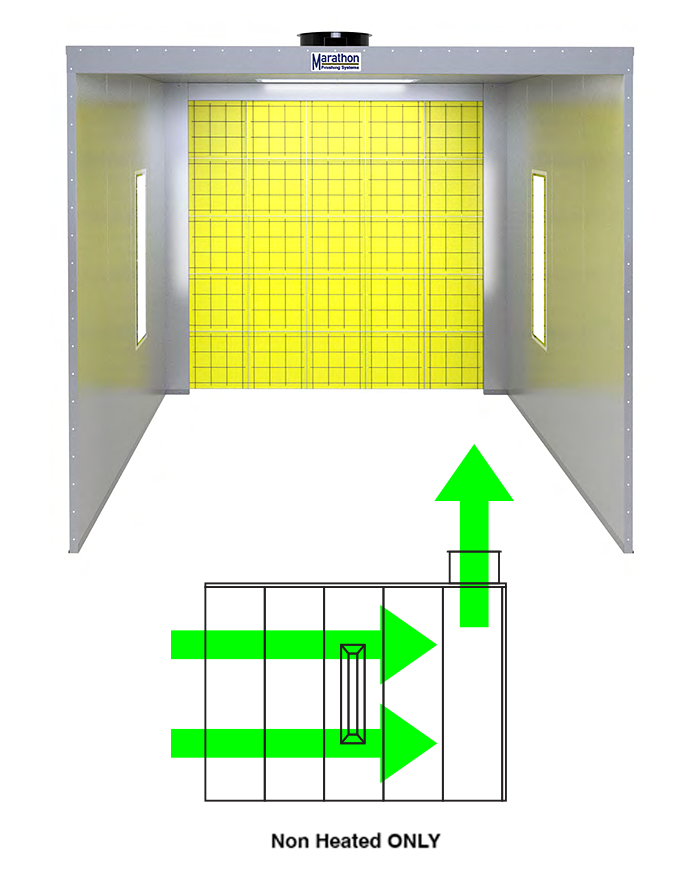

Front Air Flow

A pure Cross Flow spray paint booth. Air enters through the front door filters, travels to the rear exhaust filter plenum, and is ducted out. This design can NOT have a Spray & Cure heating option.

Industrial Open Face

A Cross Flow design, similar to the Front Air Flow, without the filtered front doors. Great for mid sized components and small runs! This design can NOT have a Spray & Cure heating option.

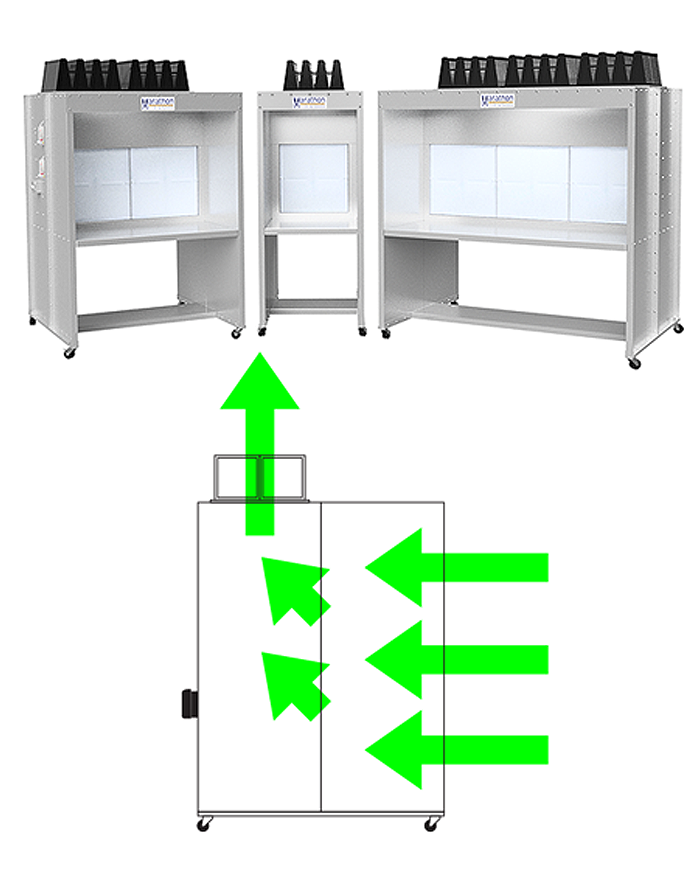

Small Parts Booths

Great for small runs of parts. Big booth results in a small booth package! Sizes from 30″ up to 76″ wide. We make ducted (without wheels) and ductless (with wheels and carbon filtration) versions.

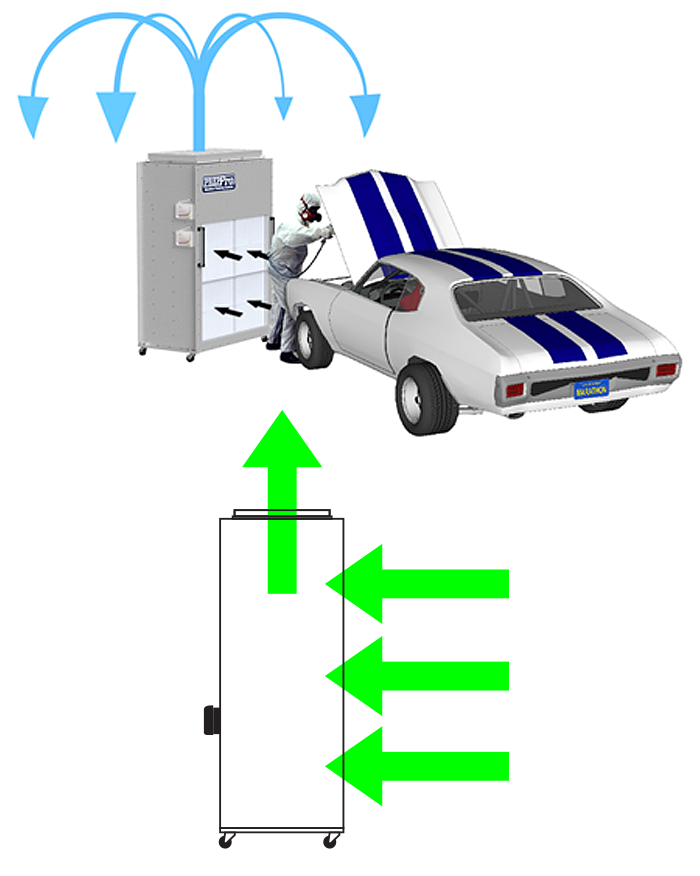

Prep Stations

Keep your environment dust free while prepping surfaces for painting! Sizes from 30″ up to 76″ wide. Ducted (without wheels) and ductless (with wheels and carbon filtration) versions available.

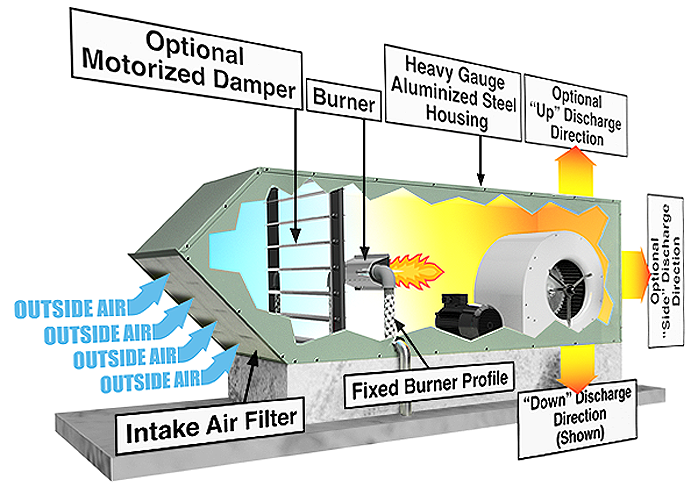

Spray & Cure Heat Systems

Energy efficient heating and curing systems found here! Do you need to add a Spray & Cure Heat System to your new spray booth order, or add one to your existing spray booth? Heat curing provides you and your customers with the best, most durable finish you can get, even if you are you are working with Waterborne paints.

Outdoor Rated

Outdoor spray paint booths can be configured as:

- Full Down Draft

- Reverse Air Flow

- Side Down Draft

Reverse Air Flow

This spray paint booth design has air enter the booth at the rear, travel horizontally (Cross Flow) to the front, where it is ducted out. Custom design and heated options available.

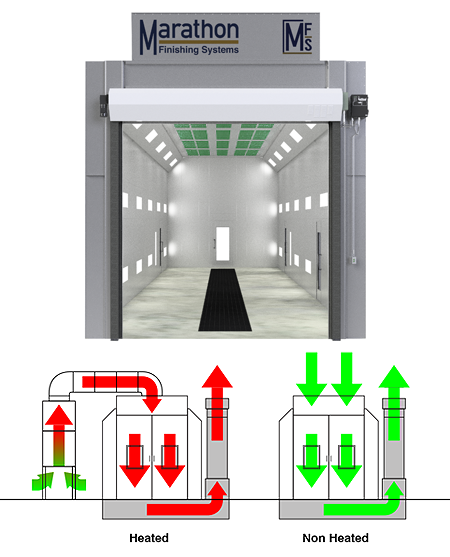

Modified Down Draft

Also known as a Semi Down Draft. Designed to be an efficient, lower cost, & high finish quality Cross Flow booth. Easy to operate and maintain. Custom design and heated options available.

Industrial Open Face

A Cross Flow design, similar to the Front Air Flow, without the filtered front doors. Great for mid sized components and small runs! This design can NOT have a Spray & Cure heating option.

Prep Stations

Keep your environment dust free while prepping surfaces for painting! Sizes from 30″ up to 76″ wide. Ducted (without wheels) and ductless (with wheels and carbon filtration) versions available.

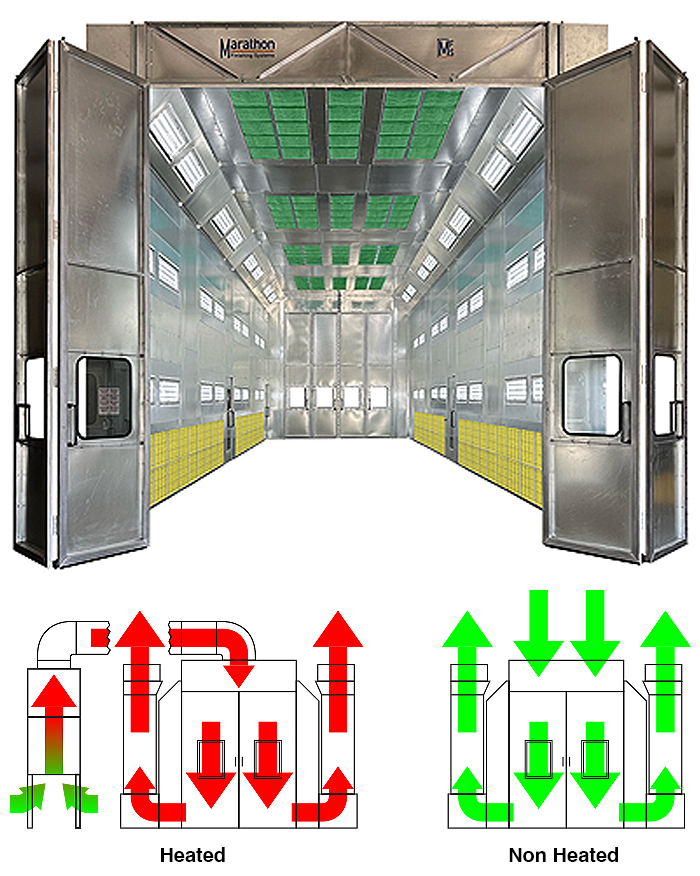

Full Down Draft

A pure down draft spray paint booth, with an exhaust pit built into the floor of the booth. Standard models or custom design. This style can be ordered with Spray & Cure Air Makeup heating.

Side Down Draft

A Down Draft without the cost of a pit. Air comes in through the top, flows down to the bottom exhausts on each side, and ducted out. Custom design and heated options available.

Front Air Flow

A pure Cross Flow spray paint booth. Air enters through the front door filters, travels to the rear exhaust filter plenum, and is ducted out. This design can NOT have a Spray & Cure heating option.

Small Parts Booths

Great for small runs of parts. Big booth results in a small booth package! Sizes from 30″ up to 76″ wide. We make ducted (without wheels) and ductless (with wheels and carbon filtration) versions.

Heating Systems

Energy efficient heating and curing systems found here! Do you need to add a Spray & Cure Heat System to your new spray booth order, or add one to your existing spray booth? Heat curing provides you and your customers with the best, most durable finish you can get, even if you are you are working with Waterborne paints.

Outdoor Rated

Outdoor Rated spray paint booths can be configured as:

- Full Down Draft

- Reverse Air Flow

- Side Down Draft

Industrial Open Face

A Cross Flow design, similar to the Front Air Flow, without the filtered front doors. Great for mid sized components and small runs! This design can NOT have a Spray & Cure heating option.

Full Down Draft

A pure down draft spray paint booth, with an exhaust pit built into the floor of the booth. Standard models or custom design. This style can be ordered with a Spray & Cure Air Makeup heating unit.

Small Parts Booths

Great for small runs of parts. Big booth results in a small booth package! Sizes from 30″ up to 76″ wide. We make ducted (without wheels) and ductless (with wheels and carbon filtration) versions.

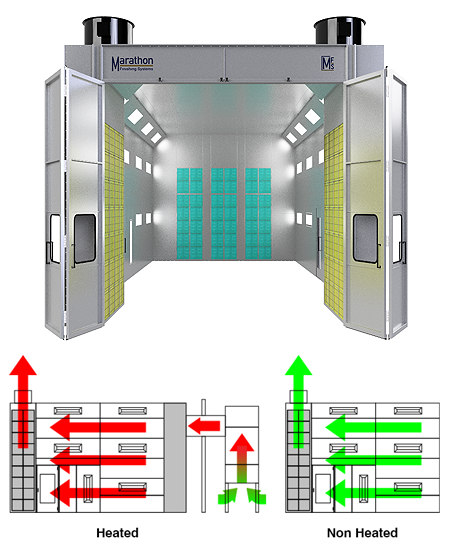

Reverse Air Flow

This spray paint booth design has air enter the booth at the rear, travel horizontally (Cross Flow) to the front, where it is ducted out. Custom design and heated options available.

Prep Stations

Keep your environment dust free while prepping surfaces for painting! Sizes from 30″ up to 76″ wide. Ducted (without wheels) and ductless (with wheels and carbon filtration) versions available.

Side Down Draft

A Down Draft without the cost of a pit. Air comes in through the top, flows down to the bottom exhausts on each side, and ducted out. Custom design and heated options available.

Spray & Cure Heat Systems

Energy efficient heating and curing systems found here! Do you need to add a Spray & Cure Heat System to your new spray booth order, or add one to your existing spray booth? Heat curing provides you and your customers with the best, most durable finish you can get, even if you are you are working with Waterborne paints.

Modified Down Draft

Also known as a Semi Down Draft. Designed to be an efficient, lower cost, & high finish quality Cross Flow booth. Easy to operate and maintain. Custom design and heated options available.

Front Air Flow

A pure Cross Flow spray paint booth. Air enters through the front door filters, travels to the rear exhaust filter plenum, and is ducted out. This design can NOT have a Spray & Cure heating option.